Category: Product News

-

What kind of hole slag can be used as raw material for sand and gravel?What are the processing equipment for hole slag?

Hole slag, usually waste generated during tunnel excavation, is mainly composed of a mixture of stones, soil and rocks.In recent years, with the continuous development of the field of construction engineering, the reuse of cave slag has become an important means of saving resources and protecting the environment.Among them, it is a common way to…

-

How to configure the limestone sand-to-gravel production line?How much is a set?

Limestone is a common building material, which is widely used in roads, bridges, buildings and other fields.In order to meet market demand, the limestone sand-to-gravel production line has gradually become the focus of industry attention.This article will introduce the configuration method of the limestone sand-to-gravel production line and the cost analysis of a set of…

-

What are the crushing and screening equipment for construction waste that works for 10 hours and produces 100 tons per hour?

With the acceleration of urbanization, the amount of construction waste generated is also increasing year by year.According to statistics, our country produces hundreds of millions of tons of construction waste every year, and most of it has not been effectively treated and utilized, which has caused great pressure on the environment.Therefore, the crushing and screening…

-

How to configure the gravel production line for breaking bluestone into 12, 13, and 24 stones?What is the price of the equipment?

With the continuous development of our country’s infrastructure construction, gravel, as an indispensable raw material in infrastructure construction, its market demand is growing day by day.As a common stone, bluestone can be broken into stones of different specifications after crushing treatment, and is widely used in roads, bridges, buildings and other engineering projects.This article will…

-

How to configure the production line of 1,000 tons of sand and gravel per hour for dolomite?How much is a set?

Dolomite is a common non-metallic mineral resource, which is widely used in construction, ceramics, glass, chemical industry and other fields.With the continuous growth of market demand, the mining and processing of dolomite has become an important industry.This article will introduce you in detail how to configure a dolomite sand and gravel production line with a…

-

What equipment is used for coal gangue crushing?What is the process flow?What is the use after crushing?

Coal gangue is a kind of solid waste produced during coal mining. Its main components are silicate, aluminosilicate and other minerals.The large accumulation of coal gangue not only occupies land resources, but also causes serious pollution to the environment.Therefore, the effective treatment and utilization of coal gangue has become an important task in the comprehensive…

-

The hourly production of more than 300 tons of vertical shaft impact crusher, which model is more suitable for your needs?How to consider the price?

With the rapid development of modern industry, the demand for efficient and high-yield crushing equipment is increasing day by day.As an advanced crushing equipment, vertical shaft impact crusher has the advantages of large crushing ratio, high production efficiency, low energy consumption and less wear.At present, there are many models of vertical shaft impact crushers with…

-

What are the special requirements for the crusher due to the high hardness of basalt?Which gravel machine can best cope with it?

Basalt is a kind of volcanic rock with high hardness, high strength and high wear resistance, which is widely used in construction, roads, railways and other fields.In view of the high hardness characteristics of basalt, the crusher needs to meet special requirements.So, what are the specific requirements for the crusher for the high hardness of…

-

What are the mining crushing machinery and equipment?How much is one?

In the mining industry, crushing machinery and equipment play a vital role.These equipment can process a variety of ores and rocks to ensure that the ores can be broken at the required particle size for further processing and processing.So, what are the mining crushing machinery and equipment?How much is one?The following will briefly introduce some…

-

What are the sand making machines with a hourly output of 300 tons?How much does this cost?

With the continuous advancement of infrastructure construction, sand making machines are more and more widely used in the construction industry.Among them, the sand-making machine with a hourly output of 300 tons has become the first choice for many companies.So, what are the sand-making machines with a hourly output of 300 tons?How much does this cost?This…

-

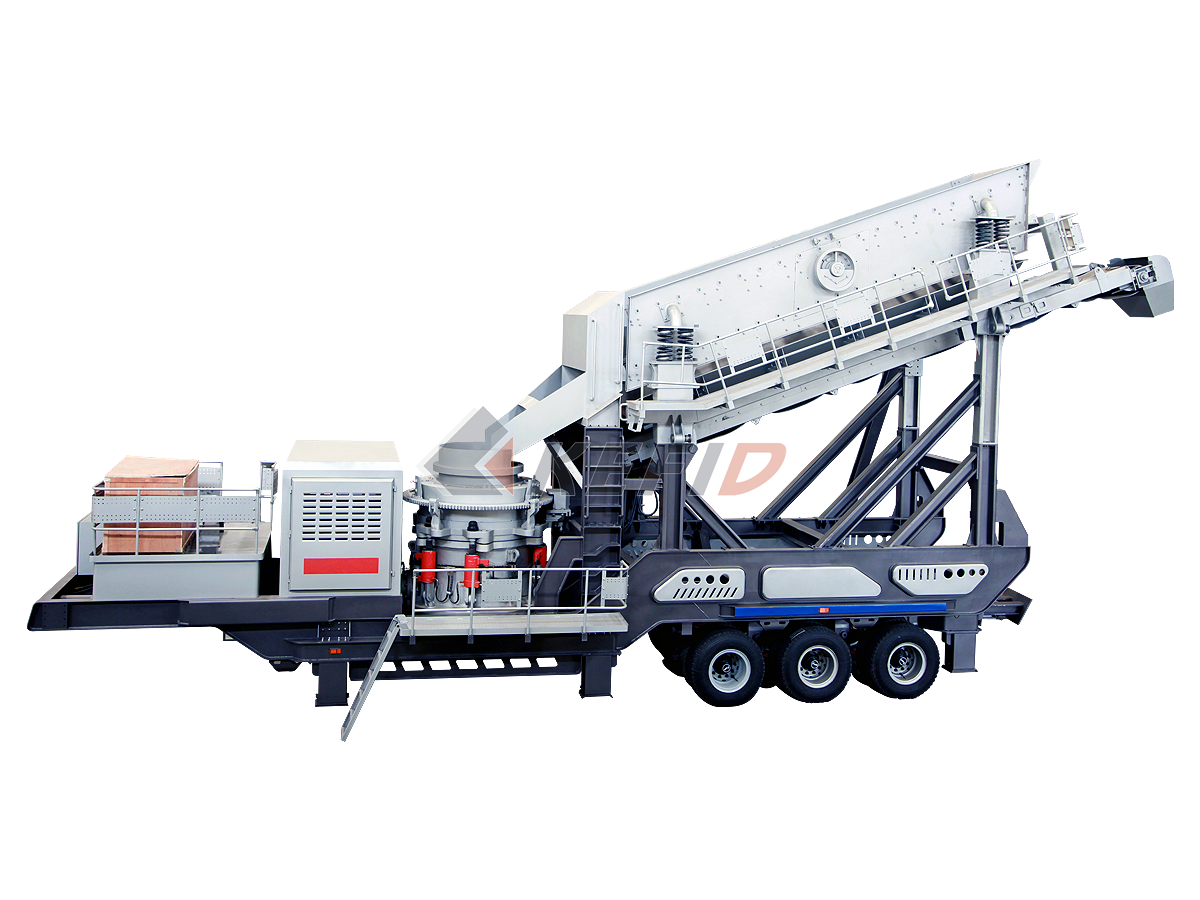

What are the configurations of mobile crushers with a hourly output of 400 tons of stone?What are the advantages of a mobile crusher with a hourly production of 400 tons of stone?

In order to meet the market demand for efficient crushing equipment, a set of mobile crushers with an hourly output of 400 tons came into being.This set of equipment not only has efficient crushing capacity, but also has the characteristics of flexible movement, which can be quickly deployed in different sites to achieve rapid crushing…

-

How does the 400-ton stone mobile crusher adapt to the crushing of stones of different properties?

With the increasing demand for mineral resources in modern society, stone crushers are becoming more and more widely used.The 400-ton stone mobile crusher with a daily output of 400 tons occupies an important position in the crushing industry because of its high degree of flexibility, energy saving and environmental protection.However, in the face of stones…

-

How to configure the iron ore crushing production line with a hourly output of 100 tons?How much does this cost?

Iron ore is an important raw material for steel production, and its quality has a direct impact on the quality of steel products.Therefore, the iron ore crushing production line, as an important part of the mineral processing link, plays a decisive role in the entire mineral processing process and product quality.In order to meet the…

-

What equipment does the bluestone crushing production line need?What is the production process?

The bluestone crushing production line is an important equipment for the production of stone, pebbles, river pebbles, gravel and other stone materials. It is widely used in road construction, construction, concrete mixing and other fields.So, what equipment does a complete bluestone crushing production line need?What is the production process? What equipment does the bluestone crushing…

-

What are the muck crushers?How much is a muck crusher?

Muck crushers play an important role in the fields of construction waste disposal, urban infrastructure construction and road laying.Facing the dazzling array of muck crusher products on the market, how to choose the product that suits your needs?What is the price?This article will answer for you. What are the muck crushers? Before purchasing a muck…

-

What equipment does the pebble sand production line with a hourly output of 200 tons need to be equipped with?Which one is good?

In the field of sand and gravel aggregate production, the pebble sand production line with a hourly output of 200 tons has become the preferred solution for many enterprises.In order to ensure the stable operation and efficient output of the production line, it is particularly important to rationally configure related equipment.This article will introduce in…

-

Recommended model of cone crusher with a hourly output of 50 tons of steel slag

At present, there are many types of steel slag cone crushers on the market, including single-cylinder cone crusher, multi-cylinder hydraulic cone crusher, full hydraulic cone crusher and composite cone crusher. Therefore, there are many options for cone crusher with a hourly output of 50 tons of steel slag.The following article recommends several models for everyone.…

-

What are the advantages of cone breaking?

Structural advantages: 1. Dilute oil lubrication and labyrinth sealing effectively block possible ways of dust pollution and improve the service life of the equipment; 2. A hydraulic safety device is designed. When encountering hard objects that cannot be broken, the iron protection can be automatically turned on to ensure that the equipment components are not…

-

How to configure the river pebble sand production line with a discharge of 0.6mm and a hourly output of 150t/h?Can the discharge mixing station be used?

The river pebble sand-making production line is an efficient sand-making process, which is suitable for the crushing and sand-making of various ore materials such as river pebbles, pebbles, granite, etc.With the rapid development of the construction industry, the demand for sand and gravel aggregates is growing day by day.Especially for engineering projects with strict particle…

-

What are the equipment for crushing basalt with a hourly output of 50 tons?How much does this cost?

Basalt, a kind of high-quality stone widely used in construction, road laying and other fields, the selection and configuration of crushing equipment is of great significance to improve production efficiency and reduce costs.This article will introduce in detail the main types of basalt crushing equipment with a hourly output of 50 tons and their prices…

-

If you want to buy VSI6X1150 vertical shaft impact crusher, what are the recommended manufacturers?

With the continuous advancement of infrastructure construction, the demand for sand and gravel aggregates is also increasing day by day.Vertical shaft impact crusher, especially the VSI6X1150 model, has become an indispensable equipment in many engineering projects due to its high efficiency, energy saving and environmental protection characteristics.When preparing to purchase such a device, it is…

-

How to configure the environmentally friendly quartz stone machine sand production line?How much is the entire production line?

With the continuous improvement of environmental awareness, green production has become an inevitable trend of enterprise development.As a kind of high-performance artificial sand, quartz stone mechanism sand is widely used in construction, concrete, mortar and other fields.This article will introduce you to the configuration and price of the environmentally friendly quartz stone machine sand production…

-

What is the working principle of a conical mobile crushing station?What are the advantages of conical mobile crushing stations in construction waste disposal?

Conical mobile crushing station is an efficient mobile crushing equipment, mainly used for coarse, medium and fine crushing of various stones and ores.It combines the advantages of a cone crusher and a mobile crushing station, and has the characteristics of high flexibility, good crushing efficiency, and easy operation.This article will introduce to you the working…

-

How to choose the right crusher according to your own production needs?What do you need to know when buying a crusher?

Crusher is an indispensable equipment in industrial production, used to break large pieces of material into small pieces for further processing and use.So, how to choose the right crusher according to your own production needs?What aspects do you need to pay attention to when buying a crusher?This article will answer these questions for you. How…

-

What are the commonly used primary crushing equipment?What is the price?

In many fields such as mining, smelting, building materials, roads, railways, water conservancy and chemical industry, crushing equipment is one of the indispensable key equipment.Among them, the first-level crushing equipment, as the first process of material crushing, is responsible for the important task of preliminary crushing of raw materials or finished products.This article will introduce…

-

What are the common configuration plans for the 500-ton sand and gravel production line with a hourly output?

Sand and gravel production lines are an indispensable part of the construction of infrastructure such as buildings, roads, and railways.With the development of technology, efficient and environmentally friendly sand and gravel production lines have become the pursuit of the industry.This article will focus on the common configuration schemes of sand and gravel production lines with…

-

What dust removal equipment should the environmentally friendly 500-ton sand and gravel production line be equipped with?

The environmentally friendly 500-ton sand and gravel production line will take into account environmental protection factors in the equipment configuration, especially in the selection of dust removal equipment.The following are some recommended dust removal equipment configurations: Crushing and sand-making equipment should be designed in a sealed manner to reduce dust generation and emissions.For example, both…

-

Impact sand making machine: sand making machine or shaping machine?What is the difference between a sand making machine and a shaping machine?

In the construction, road, concrete and other industries, sand-making equipment is an indispensable key link.As a new type of sand making equipment, impact sand making machine has attracted much attention because of its high efficiency, energy saving, environmental protection and other advantages.However, some people call it a sand making machine and some people call it…

-

What are the types of concrete pavement crushing machinery and equipment?

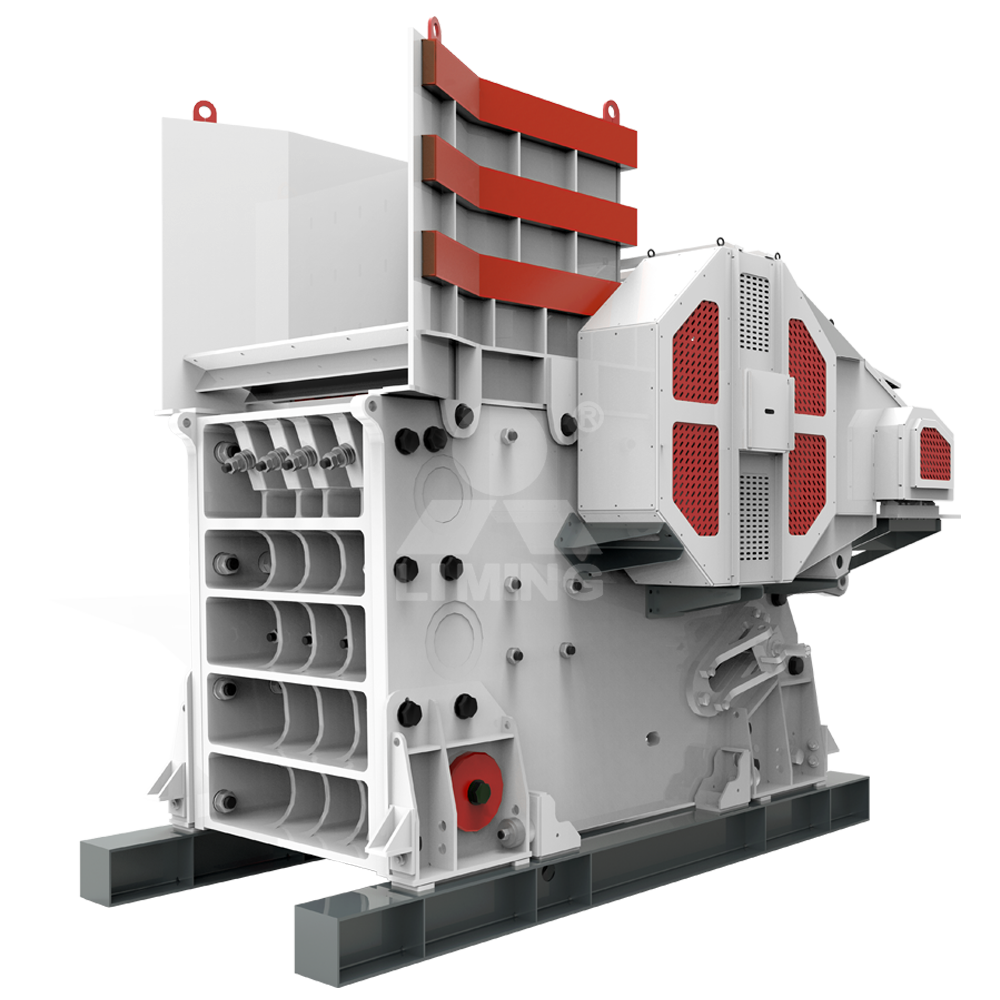

There are two types of fixed crushers and mobile crushers for concrete pavement crushing, which are suitable for different work sites and production requirements. Fixed crushers include jaw crushers, impact crushers, cone crushers, and impact crushers. Mobile crushers include tire-type mobile crushers and crawler-type mobile crushers. Let’s introduce them in detail next.:

-

Which kind of concrete pavement crushing machinery and equipment is more efficient?

When choosing concrete pavement crushing machinery and equipment, efficiency is an important consideration.However, to determine which kind of equipment is more efficient, multiple factors need to be considered comprehensively, such as the crushing capacity of the equipment, processing capacity, and energy consumption. It is suitable for areas where the factory area is large and the…