Category: Product News

-

Can the broken pebbles be used for concrete?What are the specifications of concrete gravel for construction?Which kind of crushing equipment is good?

Concrete is referred to as concrete for short. It refers to artificial stone made of cement as the main gelling material and proportionally mixed with water, sand and stone. Concrete is one of the raw materials for construction and occupies an important position in the construction industry.As the core material of the building, it helps…

-

What are the types of stone crusher equipment?How much material can be processed in a day?

There are many types of stone crushers. The commonly used ones are first breaking equipment-jaw breaking, second breaking equipment-counter breaking and cone breaking, one-time forming equipment-hammer breaking, fine crushing equipment-sand making machine and fine crushing machine, large mobile equipment-mobile breaking, each has special advantages, suitable for the production needs of certain customers, the output is…

-

How to configure a set of gravel field production line equipment?

Gravel yard equipment production lines, also known as gravel production lines, mainly produce special production line equipment for various types of construction sand and stone materials, and the development of infrastructure construction is inseparable from gravel aggregates. In recent years, with the rise of the gravel industry, more and more users in the market have…

-

Granite sand production line case site

Equipment configuration: PEW European jaw crusher, HPT hydraulic cone crusher, 5X sand making machine, vibrating feeder, YZS vibrating screen, sand washing machine, conveyor On-site situation: The material enters the 2F5X1245 vibrating feeder from the hopper, the waste is sieved out through the grate and the lower screen of the feeder, the 20-100mm material directly enters…

-

Can granite be made into mechanism sand?What equipment do you need?

Granite is a natural ore with hard texture, uniform color and good wear resistance. At the same time, it is also a high-quality building stone. It has a blocky structure, beautiful color and hard texture. It is mostly off-white and light gray. It is widely distributed in nature.Recently, there has been a situation where the…

-

How about a crawler mobile crusher for coal gangue?What are the advantages?Attached on-site case

As a solid waste discharged during coal mining and coal washing, coal gangue is harder than coal and has a relatively low carbon content. It can be applied to concrete, electric power, construction and other industries through certain processing. The processing method generally used for coal gangue is crushing and grinding. So, how about a…

-

How to configure the calcite crushing production line?What is the process flow?

Because calcite has fewer impurities and lower production costs than other raw materials (marble, limestone), there are many suppliers who need it. Before we talked about what equipment is used for calcite crushing, today we will mainly talk about how to configure the calcite production line?What is the process flow? How to configure the calcite…

-

What equipment is used for calcite crushing?How much does this cost?

Calcite is a calcium carbonate mineral that nature has given back to us. It is widely distributed, with many crystal shapes and brittle properties. It is widely used in industry, construction and other industries. Today we will tell you about what equipment is used for calcite crushing?How much does this cost? What equipment is used…

-

What is the difference between a cone crusher and a impact crusher?

Cone crusher and impact crusher are indispensable two-breaking equipment in large and small production lines. Many customers do not know the difference, so there will be difficulties in choosing. In fact, because of the differences in various aspects, the two also have their own strengths in specific production.Today we will talk in detail about the…

-

How to choose whether to use a cone crusher or a counterattack crusher for crushing?

The same is crushing. Many people will wonder why cone crushers are sometimes recommended and counterattack crushers are sometimes recommended. From this, Xiaobian thought that there may be many friends who are new to the crushing industry who don’t know much about the two types of equipment, cone breaking and counterattack breaking, so Xiaobian’s article…

-

How to choose the type of iron ore cone crusher?What factors need to be considered when purchasing an iron ore cone crusher?

Under normal circumstances, iron ore has high hardness and abrasive properties. Therefore, iron ore processed by cone crushers can be widely used in construction, chemical industry and other industries to realize its various application values as a resource. So, how to choose the type of iron ore cone crusher?What factors do you need to consider…

-

How to choose a sand making machine for processing fine aggregates?How much is one?

In the engineering fields of construction, roads, bridges, etc., high-quality aggregates are indispensable and important materials. In order to obtain high-quality high-quality aggregates, it is particularly important to choose suitable sand-making machine equipment.This article will provide you with guidance on choosing a sand making machine for processing high-quality aggregates, and help you choose a satisfactory…

-

What are the types of rock crushers?What are the advantages and disadvantages?

Rock crusher is an important large-scale crushing equipment, mainly used to crush hard rocks, ores and other materials, in order to achieve material pretreatment, resource utilization and other purposes.It has been widely used in mining, building materials, road construction and other fields.This article will introduce the common types of rock crushers and their characteristics, and…

-

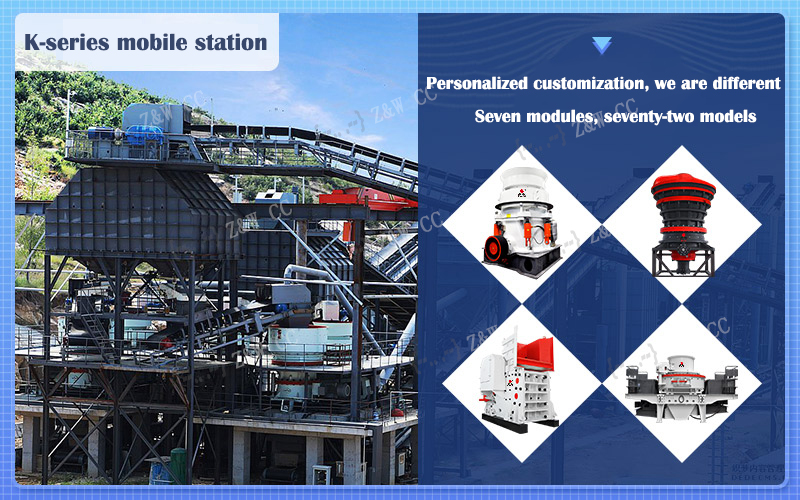

What are the recommendations for mobile sand and gravel production equipment with a hourly output of 50-80 tons?How is the processing effect?

With the continuous development of the construction industry, the demand for sand and gravel as one of the main raw materials for concrete is also increasing.In order to meet this demand, mobile sand and gravel production equipment with a hourly output of 50-80 tons has gradually become a popular equipment on the market.So, what are…

-

What are the equipment of the crushing production line with a hourly output of 600 tons?How to choose?

The crushing production line equipment with a hourly output of 600 tons is the core equipment widely used in mining, construction and other fields.The efficiency and capacity of this kind of production line equipment are of great significance for industrial production.This article will introduce in detail the crushing production line with a hourly output of…

-

How to configure the river pebble crushing production line?What are the plans?

The river pebble crushing production line uses a series of machinery and equipment to break large pieces of river pebbles into gravel of different specifications to meet the needs of construction projects, road construction and other industries.So how to configure the river pebble crushing production line?What are the plans?Today we will talk about it in…

-

What is the equipment for the silica crushing and processing production line with a hourly output of 100-150 tons?How much does this cost?

The hourly production of 100-150 tons of silica crushing and processing production line equipment is a professional industrial production line equipment, which is mainly used to break large pieces of silica raw materials into small particles for further processing or use.The selection and use of the production line equipment needs to be rationally configured according…

-

What are the molybdenum ore processing and production equipment?What is the process flow?

Wow, do you know?Molybdenum ore is a super useful mineral, just like some artifacts in our lives, it has a wide range of uses!It can be seen in the fields of steel, chemical industry, electronics and aviation.But if you want to dig out the treasures in the molybdenum mine, you have to have a set…

-

What are the crushing and processing equipment for potassium feldspar?What is the process flow?

Potassium feldspar is a common silicate mineral with high economic value and a wide range of applications.In the processing process of potassium feldspar, the selection of crushing equipment and the design of the process flow are essential.This article will introduce the equipment and process flow of potassium feldspar crushing and processing in detail. Selection of…

-

How should the pavement stone production line be configured?Is there any reliable manufacturer that can recommend it?

Earlier, we talked about the selection of equipment for the pavement stone production line and the factors that need to be taken into account. Today we will talk about how to configure the pavement stone production line?And recommend a reliable production line configuration manufacturer for you. How should the pavement stone production line be configured?…

-

What are the options for pavement stone production line equipment?What factors need to be considered?

With the continuous advancement of infrastructure construction, the demand for pavement stones, as one of the important building materials, is also increasing day by day.In order to meet this demand, it is essential to choose the right pavement stone production line equipment.This article will introduce the types of equipment for pavement stone production lines and…

-

How to choose a complete set of slag crushing equipment?What is the process flow?Configuration plan of complete equipment for slag crushing with slag

The complete set of slag crushing equipment is mainly used to crush slag for subsequent reuse.Before formulating the configuration plan, it is necessary to have a detailed understanding of the material characteristics, production requirements and environmental protection standards of the slag.Today we will introduce how to choose a complete set of slag crushing equipment?What is…

-

What are the advantages of Liming Heavy Industry concrete crushing treatment equipment?What equipment are there?

Concrete crushing and treatment equipment is widely used in various industries, such as industrial production, construction industry and maintenance industry.In these fields, concrete crushing and treatment equipment plays an important role in crushing, screening and reusing waste concrete, thereby reducing dependence on natural resources, reducing costs, and contributing to environmental protection.Today we will talk about…

-

What are the dolomite compound crushers?What is the principle of crushing?

As an important non-metallic mineral resource, dolomite is widely used in construction, chemical industry, metallurgy and other fields.In order to meet market demand and improve the utilization rate of dolomite, dolomite composite crusher came into being.This article will introduce you to the types and crushing principles of dolomite composite crushers. Types of dolomite composite crusher…

-

How to choose the right aluminum ore processing equipment?What is the workflow of aluminum ore processing?

Aluminum ore processing equipment is equipment used to crush, grind, refine, etc. aluminum ore, and is an important part of the aluminum industry.With the rapid development of our country’s economy, the demand for aluminum industry is growing day by day, and the position of aluminum ore processing equipment in the aluminum industry is becoming more…

-

What equipment is used in the calcite crushing production line?How much does this cost?(With process flow)

As a widely used non-metallic mineral, calcite has attracted much attention in mining and processing.In recent years, with the development of science and technology and the improvement of environmental protection requirements, the calcite crushing production line equipment has also been continuously updated and upgraded.This article will reveal the common equipment and prices of calcite crushing…

-

How to configure the 800-ton tuff crushing production line at a time?

With the continuous advancement of infrastructure construction in our country, tuff, as a common building material, the market demand is increasing year by year.In order to meet market demand and improve production efficiency, a tuff crushing production line with an hourly output of 800 tons has become a necessary choice. Production line equipment selection and…

-

What are the silica crushers?

Silica mine crusher is an indispensable equipment in the silica processing process. Choosing a crusher that suits you can not only improve production efficiency, but also reduce production costs.So, what silica crushers are there on the market?This article will answer for you. Jaw crusher: The jaw crusher has the advantages of simple structure, large crushing…

-

How to choose the right silica mine crusher equipment for you?

Choosing the right silica mine crusher equipment for you needs to consider the following factors: 1.The nature of the broken material: Silica has high hardness and stable chemical properties, so it is necessary to choose equipment with high crushing capacity.Generally speaking, both jaw crushers and cone crushers can cope with the crushing needs of silica.…

-

How about a 100-ton moving stone crusher with a hourly output?

With the continuous acceleration of infrastructure construction in our country, the demand for stone crushers is growing day by day.As an important building material, the demand for stone depends to a large extent on the performance and output of crushing equipment.Today, let us learn about a high-efficiency and energy-saving 100-ton mobile stone crusher with hourly…