Mindblown: a blog about philosophy.

-

What are the factors that affect the output of a machine that moves broken stones?

In the production process of sand and gravel materials, the mobile crushing machine purchased by the user is difficult to reach the production capacity stated in the manual. At this time, the user may suspect whether the equipment has been bought at a loss. Here we suggest that you do not panic when facing this…

-

What are the crushing machinery and equipment? Production process of stone crushing machinery and equipment

There are many crushing machinery and equipment, including primary crushing, secondary crushing, and fine crushing, as well as feeders, conveyors, and screening equipment. The whole set of equipment can have different configuration schemes according to customer needs and processing materials, so how much is a set of crushing machinery? What are the crushing machinery and…

-

What is the reason for the slow start of the Raymond mill?

Raymond mill is an indispensable equipment for the industrial milling industry, and has made great contributions to major milling industries. Some users have reported that Raymond mill will have some problems after using it for a period of time , For example, the startup speed is too slow when starting, and sometimes it takes several…

-

Can the vertical shaft impact crusher make sand, and how much is the price to buy one?

Vertical shaft impact crusher is also called impact sand making machine. It is mainly used for fine crushing of stone materials and can crush more than 200 kinds of materials such as granite, quartz, basalt, river pebble, limestone, dolomite, etc. Its unique design , outstanding advantages, very popular with investment users, but some people still…

-

What are the models of 500 tons per hour gravel crusher? What is the price?

Nowadays, the sand and gravel market is still hot, and the demand for stones is also increasing. Stones are processed by crushing equipment from rocks in nature. Under the current situation, large-scale stone production equipment is very popular. Today we will introduce the time What are the models of the 500-ton quarry crushing stone crusher?…

-

How much does construction waste mobile crushing equipment cost? Is it possible to customize special mobile crushing equipment?

Construction waste mobile crushing equipment is also called mobile construction waste treatment equipment. It is a multi-functional and integrated crushing and screening equipment. The installation time and transportation cost are reduced, the crushing is easier, it is widely used in the market, and the price is more expensive than other crushing equipment, probably hundreds of…

-

Large river pebble sand making machine – how much is a sanding machine? (Attachment picture attached)

The main function of the river pebble sand making machine is to break the river pebbles into sand below 5mm. It not only meets the market demand for gravel, but also brings effective benefits to the boss. River pebble sand making machine is also called river pebble grinding machine and river pebble sand making machine.…

-

What are the stone crushing machines for breaking cement blocks? Manufacturers recommend

In the process of house demolition, road repair will produce a large amount of construction waste, including cement blocks, this waste cement blocks should do? In fact, if handled properly, it can also be turned into treasure, this time you need to use our stone crusher, so, what are the crushing cement block crusher? Here…

-

What about construction waste? Mobile crushing plant to help you!

With the development of cities and the rise of various buildings, a large amount of construction waste will be generated. In addition to a part of these construction waste is used for recycling classification and reuse, the rest are dumped indiscriminately, which not only seriously affects the beauty of the urban environment, but also brings…

-

How to choose mobile crusher and stationary crusher? What are the types of mobile crushers?

For the bosses who are just involved in the field of sand and gravel crushing, the choice of mobile crusher and stationary crusher is often very tangled, do not know which one is good, today we have a mobile crusher and stationary crusher how to choose? What are the types of mobile crusher? To solve…

-

What equipment is needed for river pebble sand making machine production line? With river pebble sand making process

River pebble is a common construction aggregate, and the sand made by sand making production line has uniform size and good grain shape. Compared with natural sand quarrying, river pebble sand making can save a lot of cost, so it is welcomed by the market. So, what equipment is needed for river pebble sand making…

-

How much is a river pebble cone crusher? Cone crusher manufacturer recommendation

River pebble is a hard, wear-resistant, chemically stable silicate mineral, which is an important industrial mineral raw material after crushing, sand making and screening. Today we will mainly talk about the river pebble crushing stage, then there will be many bosses curious about how much the river pebble cone crusher? What are the recommendations of…

-

What equipment is needed for a quarry plant?

Stone plant is mainly limestone, basalt or granite and other raw materials of various ores without chemical treatment, made by mechanical crushing, particle size is usually 5-60mm stone, for various industries to provide aggregates, the development scenario in recent years is also very good, but what equipment is needed to start a stone plant? How…

-

How is lithium ore processed? What equipment is used?

Typical lithium ore is divided into lithium pyroxene, perovskite feldspar, lithium mica and so on. With the development of science and technology, the era of progress, the rise of new energy industry, which makes some rare resources are reused, including lithium ore, then, how is lithium ore processing? What equipment do you need to use?…

-

How to choose lithium pyroxene grinding equipment selection?

Lithium pyroxene is a kind of lithium ore, the crystals are usually columnar, granular or plate-like, as lithium chemical raw materials, widely used in lithium chemical, glass and ceramic industries. So, how to choose the selection of lithium pyroxene grinding equipment? Lithium pyroxene grinding equipment selection Lithium pyroxene grinding is generally divided into coarse powder…

-

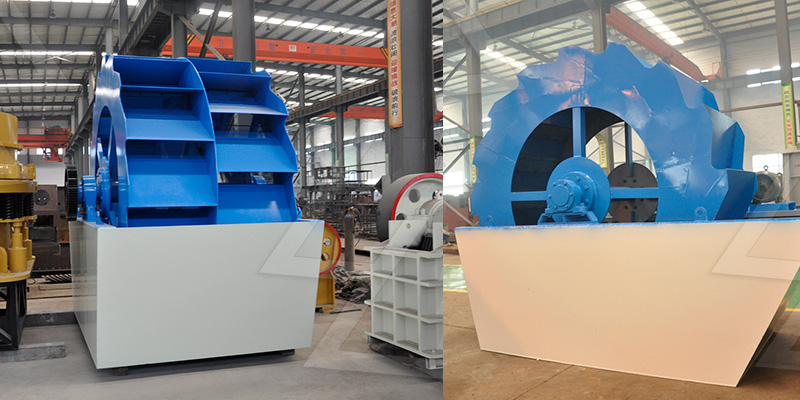

How about stone cleaning machine equipment?

Stone is natural rock, pebbles or mining waste stone made by mechanical crushing, screening, particle size greater than 4.75mm particles, which will contain some impurities, will choose stone cleaning machine to clean, which will be mud, ash powder off wash and screening operations, to achieve the purpose of purification, how about the current stone cleaning…

-

Electronic grade lithium carbonate preparation grinding machine selection

The development of new energy vehicles has pushed some metal mines to the forefront, and the battery is the power core of new energy vehicles. Lithium carbonate is a high-end application material, which has high application value in the battery industry. Lithium carbonate is the basic raw material for lithium salt industry, not only can…

-

Advantages of potassium feldspar vertical grinding mill

1、Low investment cost. The equipment integrates crushing, drying, grinding and classifying and conveying in one, with simple system, compact layout, less floor space, and can be arranged in the open air, saving a lot of investment cost. 2、Easy operation and maintenance. (1)Equipped with automatic control system, which can realize remote control and easy operation. (2)Equipped…

-

Potassium feldspar vertical grinding mill working principle_Potassium feldspar vertical grinding mill recommended

In recent years, with the development of glass and ceramic industries, the products are increasingly high-grade, and I over the demand for high-purity subway potassium feldspar is also increasing. Potassium feldspar is rich in resources, but contains iron and carbon beyond the standard, therefore, potassium feldspar in addition to iron is the key to purification,…

-

250tph granite crushing line in Zambia

One of our state-owned enterprise customers bought one set of equipment of 250tph for granite crushing. The whole production line is running smoothly, especially the single cylinder hydraulic cone crusher performs outstanding. The equipment we equipped meet our customer’s need, and the final product are suitable for infrastructure construction.Z&W CC has the right crushing, grinding…

-

600tph river stone sand making production line in Shanxi, China

The customer responsible for this project has already used products made in Liming Heavy Industry since 2013. He bought 8 sets of HPT300 cone crusher and 8 sets of 5X1145 sand making machine. Based on the trust, the customer choose Liming Heavy Industry again in this extension project and they continue the cooperation. After the…

-

300tph granite crushing line in Uzbekistan

The project is mainly used to process granite for concrete. In the process of production, materials larger than 100mm enter JC840x1100 jaw crusher through vibrating feeder for primary crushing. Then they are fed into HPT300C multiple cylinder hydraulic cone crusher by belt conveyor for secondary crushing. After crushing, materials are screened by vibrating screen 3YZS1860…

-

250tph basalt crushing line in Batangas, Philippines

The project processes basalt, which is ultimately used for building materials. This production line adopts two-stage crushing process. Vibration feeder conveys materials to jaw crusher for coarse crushing, then cone crusher will process them for medium and fine crushing. After screening, the finished product is obtained, and the unqualified materials are returned to cone crusher…

-

European Impact Crusher for Copper ore slag in Zambia

The evaluation from customer: I am satisfied with the quality and technology of the after sales services. The machines are running very well and the capacity is beyond my expectations. The hydraulic adjustment of the European Type Impact Crusher reduces the maintenance time greatly. I have purchased another production line at the end of 2014.…

-

2000tpd gold ore crushing line in South Africa

The evaluation from customer: The stable mechanical properties has realized the full automation of the production line, saving time and effort. We require 3.8 t/m3 for the final particule granularity, so the engineer proposed two Hydraulic Cone Crusher HPT300, assisted by a Ball Mill Φ2700X3600 and a Jaw Crusher PE750X1060. This production line has well…

-

2000tpd gold ore upgrading project in China

The evaluation from customer: The stable mechanical properties has realized the full automation of the production line, saving time and effort. We require 3.8 t/m³ for the final particle granularity, so the engineer has proposed four mills, assisted by eight Ball Mill and two stages of flotation machine. This production line has also well met…

-

Ball mill for iron ore beneficiation in India

The evaluation from customer: In this benefication project, we used 3R2715 ball mill to process iron ore. The input size is 15-20mm and the output size is 0.075mm. The result is satisfying me very much, so I think Liming Heavy Industry is a perfect choice. The configuration of ball mill for iron ore benefication in…

-

4500tpd magnetite ore processing project in Malaysia

The evaluation from customer: Because of our high requirements for final particule granularity, I have followed the views of LIMING engineer with a two-stage crushing: a PE Jaw Crusher for primary crushing and two Hydraulic Cone Crusher HST160 for secondary crushing. Quite stable performance and the production makes me satisfied. To my most pleasant surprise,…

-

120tph gold ore crushing line in Kazakhstan

These are two gold crushing production lines with the same configuration. The project headquarters is the Chimkent, with mines in Turkestan and Ustinka, Myanogorsk, respectively. The technological process is simple and clear. Material enters jaw crusher for primary crushing and cone crusher for secondary crushing. The final product size is about 20 mm. The configuration…

-

200tph iron ore crushing line in Kazakhstan

The mine of this project is located in Chimkent. It adopts the two-stage crushing mode consisting of jaw crusher and cone crusher. The size of iron ore raw material is about 600 mm. After crushing, the finished product of 20 mm can be obtained. The configuration of 200tph iron ore crushing line in Kazakhstan Place…

Got any book recommendations?