A nickel process flowsheet outlines the steps involved in extracting and refining nickel from its ores. The exact flowsheet depends on the type of nickel deposit (sulfide ores vs. laterite ores) and the chosen processing route. Below are simplified flowsheets for both major types:

—

1. Nickel Sulfide Ore Processing (Pyrometallurgical Route)

Sulfide ores (e.g., pentlandite) are typically processed via flotation, smelting, and refining.

Flowsheet Steps:

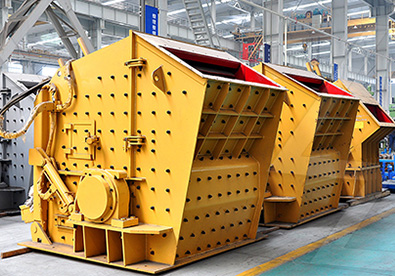

1. Crushing & Grinding: Ore is crushed and ground to liberate nickel-bearing minerals.

2. Froth Flotation: Separation of nickel sulfides from gangue minerals using reagents; produces a nickel concentrate (~10–20% Ni).

3. Smelting:

– Concentrate is dried and fed into a flash smelter or electric furnace (~1,200–1,350°C).

– Produces a molten matte (Ni-Cu-Fe-S) and slag (discarded).

4. Converting: Matte is oxidized in a converter to remove iron/sulfur, yielding high-grade matte (~75% Ni + Cu).

5. Electrorefining or Leaching:

– Electrorefining: Matte is cast into anodes and refined electrolytically to produce pure cathode nickel (>99.9% Ni).

– Pressure Acid Leaching: Alternative hydrometallurgical route for matte dissolution followed by solvent extraction/electrowinning (SX-EW).

Key Byproducts: Copper, cobalt, platinum group metals (PGMs).

—

2. Nickel Laterite Ore Processing (Hydrometallurgical/Pyrometallurgical Routes)

Laterites (oxide ores) require different approaches due to their low-grade (~1–3% Ni) and high iron content.

(A) High-Pressure Acid Leach (HPAL) – Hydrometallurgical Route

1. Ore Preparation: Crushing and slurry formation with sulfuric acid.

2. Leaching: Slurry is heated (~250°C) under pressure to dissolve nickel/cobalt into solution.

3. Neutralization & Precipitation: Impurities (Fe, Al) are removed via pH adjustment; solution undergoes sulfide precipitation or solvent extraction (SX).

4. Electrowinning: Nickel/cobalt are recovered as cathodes or salts (>99% purity).

(B) Rotary Kiln Electric Furnace (RKEF) – Pyrometallurgical Route

1. Drying & Calcination: Laterite ore is dried and heated (~700°C) to remove moisture/volatiles.

2. Reduction Smelting: Ore is mixed with reductants (coal/coke) and melted in an electric furnace (~1,500°C), producing ferronickel (~20–40% Ni).

3. Refining: Ferronickel is further refined by sulfur/phosphorus removal or converted into nickel matte.

—

Simplified Flowsheet Diagrams:

- [Sulfide Ore Flowsheet](https://www.mining-technology.com/wp-content/uploads/sites/8/2023/02/Nickel-Sulfide-Processing-Flowsheet.png) (Example): Flotation → Smelting → Converting → Electrorefining.

- [Laterite HPAL Flowsheet](https://www.researchgate.net/figure/Schematic-flowsheet-of-the-HPAL-process-for-nickel-laterite-ores_fig2_334715358) (Example): Leaching → SX → Electrowinning.

- Sulfide ores are easier/more economical but depleting; laterites dominate reserves but are energy-intensive.

- Environmental factors: HPAL generates acidic waste; RKEF has high CO₂ emissions.

- Emerging technologies include bioleaching for sulfides and atmospheric leaching for laterites.

—

Key Considerations:

Would you like details on a specific stage or alternative processes like Caron process?

Leave a Reply