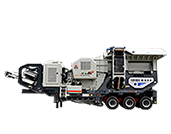

An iron ore crusher stone crushing plant in Jabalpur would involve several stages of processing to break down large iron ore rocks into smaller, usable sizes for further beneficiation or direct use. Here’s an overview of what such a plant might entail:

1. Location & Raw Material

- Jabalpur, in Madhya Pradesh (India), is rich in mineral resources, including iron ore deposits.

- The plant would source raw iron ore from nearby mines (e.g., Balaghat, Katni, or Jabalpur district itself).

- Large iron ore rocks (up to 1.5m) are fed into a primary jaw crusher (e.g., 600×900 mm).

- Output: ~150–200 mm sized chunks.

- The crushed material is further reduced using a cone crusher (for hard ores) or an impact crusher (for softer ores).

- Output: ~20–50 mm particles.

- For finer crushing, a Vertical Shaft Impactor (VSI) or another cone crusher may be used.

- Output: ~5–20 mm for pelletizing or sintering.

- Vibrating screens separate crushed material into different sizes for further processing.

- Oversized material is recirculated back into the crushers.

- Feeders & Conveyors: For smooth material flow between stages.

- Dust Suppression System: To control airborne dust (important for compliance with pollution norms).

- Magnetic Separators: To remove tramp iron and improve purity before further beneficiation.

- A 100–200 TPH plant may require a 100–200 HP motor.

- Land requirement: ~1–2 acres for the setup.

- The plant must follow guidelines from the Madhya Pradesh Pollution Control Board (MPPCB) and obtain necessary permits (Consent to Establish/Operate under Air & Water Acts).

- Sent to steel plants (e.g., Bhilai Steel Plant) for smelting.

- Used in pelletization plants or exported via rail/road from Jabalpur’s logistics hubs.

2. Crushing Process

A typical iron ore crushing plant includes the following stages:

Primary Crushing (Jaw Crusher)

Secondary Crushing (Cone Crusher / Impact Crusher)

Tertiary Crushing (VSI Crusher / Fine Cone Crusher – Optional)

3. Screening & Classification

4. Auxiliary Equipment

5. Power & Infrastructure Requirements

6. Pollution Control & Compliance

7. End Use of Crushed Iron Ore

Would you like details on specific machinery suppliers or regulatory approvals for setting up such a plant in Jabalpur?

Leave a Reply