A roller mill used for tourmaline processing is designed to crush, grind, or pulverize tourmaline minerals into fine powders or specific particle sizes for various industrial applications. Tourmaline is valued for its piezoelectric and pyroelectric properties, making it useful in electronics, water purification, cosmetics, and health products.

Key Features of a Roller Mill for Tourmaline Processing:

1. Crushing & Grinding Mechanism:

– Uses two or more rollers to apply compressive force on tourmaline crystals.

– Adjustable gap settings control particle size (from coarse granules to ultrafine powder).

2. Material Compatibility:

– Made from hardened steel or ceramic rollers to resist wear from abrasive tourmaline.

– May include cooling systems if heat-sensitive processing is required. .jpg)

3. Particle Size Control:

– Equipped with sieving or air classification systems for uniform particle distribution.

4. Dust Collection System:

– Prevents airborne particles (important due to tourmaline’s potential respiratory hazards).

5. Automation & Adjustability:

– Some models feature digital controls for speed, pressure, and feed rate optimization.

Applications of Processed Tourmaline Powder:

- Cosmetics & Skincare: Used in facial masks, creams (for negative ion emission).

- Water Treatment: Enhances filtration due to its electrolytic properties.

- Electronics: Piezoelectric components (sensors, pressure gauges).

- Health Products: Far-infrared therapy mats, ionizing bracelets.

- Raymond Roller Mill – For fine grinding (~50–325 mesh).

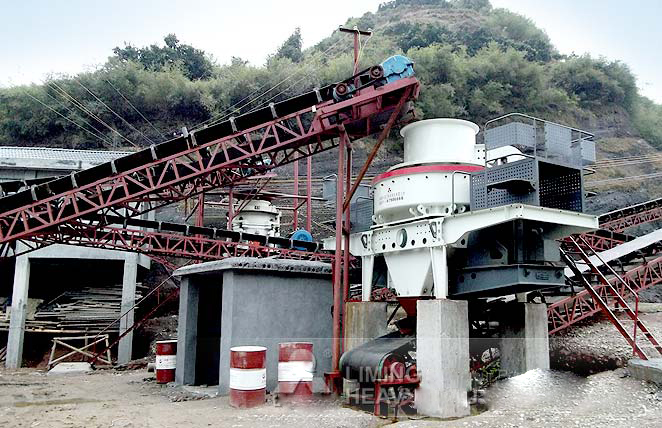

- Vertical Roller Mill (VRM) – Energy-efficient for large-scale production.

- High-Pressure Grinding Roller (HPGR) – For ultra-fine micronization.

- Hardness of tourmaline (~7–7.5 Mohs) requires durable rollers.

- Moisture content may affect grinding efficiency (pre-drying may be needed).

- Desired fineness determines mill type and classifier integration.

Popular Roller Mill Types Suitable for Tourmaline:

Considerations When Choosing a Machine:

Would you like recommendations on specific brands or additional processing steps like magnetic separation?

Leave a Reply