A mill system for Flue Gas Desulfurization (FGD) is a critical component in wet limestone-based FGD systems, used primarily in coal-fired power plants to remove sulfur dioxide (SO₂) from exhaust gases. The mill grinds limestone into fine particles to create a slurry, which reacts with SO₂ in the absorber vessel.

Key Components of an FGD Mill System

1. Limestone Feed System

– Delivers raw limestone (typically 90% CaCO₃) from storage to the mill.

– Includes feeders, conveyors, and sometimes pre-crushers.

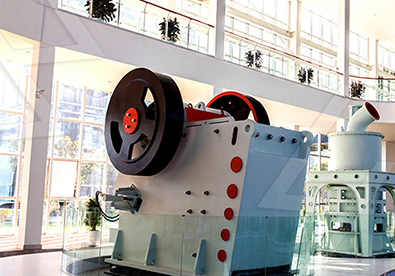

2. Wet Ball Mill or Vertical Roller Mill

– Wet Ball Mill: Most common; grinds limestone with water to produce slurry (~30% solids).

– Vertical Roller Mill: More energy-efficient alternative for dry grinding (later mixed with water).

3. Slurry Storage Tank

– Holds ground limestone slurry before it’s pumped to the absorber.

– Equipped with agitators to prevent settling.

4. Slurry Pumping System

– Transfers slurry from the mill circuit to the absorber spray nozzles.

– Includes recirculation loops for optimal particle size control.

5. Hydrocyclone Classifier (Optional)

– Separates oversized particles for regrinding, ensuring proper fineness (~90% passing 325 mesh/44 µm).

6. Water Supply System

– Provides process water for slurry preparation and mill cooling.

7. Control & Monitoring Systems

– Adjusts feed rate, water ratio, and grinding efficiency based on SO₂ removal demands.

Process Flow

Process Flow

1. Raw limestone is fed into the mill along with water.

2. The mill grinds limestone into fine particles (~20–50 µm).

3. Slurry flows to a storage tank where it’s homogenized.

4. Slurry is pumped into the FGD absorber tower, where it reacts with SO₂:

\[

\text{CaCO₃} + \text{SO₂} + \frac{1}{2}\text{O₂} + 2\text{H₂O} → \text{CaSO₄·2H₂O} + \text{CO₂}

\]

5. Waste byproduct (gypsum) is dewatered for disposal or reuse.

Design Considerations

Design Considerations

– Grinding Efficiency: Affects reagent

Leave a Reply