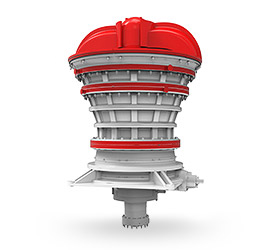

The concave and mantle are critical components of a cone crusher, responsible for the crushing action. Here’s a breakdown of their roles, differences, and maintenance considerations:

1. Cone Crusher Concave & Mantle Functions

– Concave (Fixed Liner):

– A stationary outer surface that forms the crushing chamber.

– Acts as the surface against which the mantle crushes the material.

– Typically made of high manganese steel or other wear-resistant alloys.

– Mantle (Moving Liner):

– The rotating inner component that gyrates within the concave.

– Compresses and crushes rock/ore against the concave.

– Also made from wear-resistant materials but wears faster than the concave.

2. Key Differences

| Feature | Concave | Mantle |

|—————|———|——–|

| Position | Outer stationary part | Inner moving part |

| Movement | Fixed (attached to bowl) | Moves eccentrically |

| Wear Rate | Slower (due to less direct impact) | Faster (due to constant movement) |

| Shape | Curved inward to form chamber | Conical shape matching concave |

3. Wear & Replacement

3. Wear & Replacement

– Both parts wear over time due to abrasion and compression.

– Uneven wear can reduce crushing efficiency or cause damage.

– Signs of wear:

– Reduced throughput.

– Poor product size/shape.

– Increased power consumption.

– Replace when worn beyond tolerance (~60–70% loss).

4. Material Selection

Common materials include:

– Manganese steel (Mn14%, Mn18%, Mn22%) – Good toughness & work hardening.

– Chrome-moly alloys – Higher abrasion resistance for hard rock.

– Composite alloys – For extreme conditions.

5. Maintenance Tips

1. Regularly check liner thickness with gauges.

2. Monitor feed size to avoid excessive wear from oversized material.

3. Ensure proper crusher settings (CSS – Closed  e Setting).

e Setting).

4. Rotate/swap concaves if asymmetrical wear occurs.

6. OEM vs Aftermarket Parts

– OEM parts ensure exact fit but are costly.

– Aftermarket alternatives can be cost-effective but vary in quality.

Would you like details on installation procedures or troubleshooting specific issues?

Leave a Reply