A cage mill grinder is a type of size reduction equipment used in various industries to crush, grind, or pulverize materials. It consists of one or more rotating cages with pins or bars that impact and break down the material through collision and shear forces.

Key Features of a Cage Mill Grinder:

Key Features of a Cage Mill Grinder:

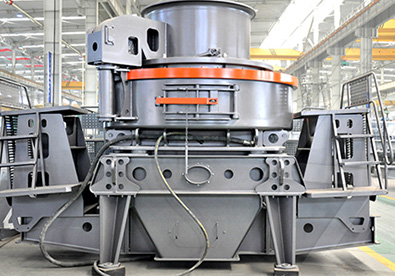

1. Design:

– Contains one or more rotating cages (often two counter-rotating cages).

– Pins, bars, or breaker plates inside the cages create high-impact collisions.

– No screens (grinding occurs by impact rather than compression).

2. Applications:

– Fertilizer processing (crushing granules into powder).

– Mineral and aggregate grinding (limestone, gypsum, phosphate rock).

– Coal and petroleum coke pulverization.

– Recycling (glass, electronic waste).

3. Advantages:

– High reduction ratio in a single pass.

– Handles wet or sticky materials better than some mills.

– Low maintenance (no screens to clog).

4. Disadvantages:

– Higher wear on pins/bars compared to some grinding methods.

– May produce more fines than desired in some applications.

Common Manufacturers & Models:

Common Manufacturers & Models:

– Stedman Machine Company (H-Series, F-Series)

– Williams Patent Crusher (Cage Mill Pulverizers)

Would you like details on specific models or operational best practices?

Leave a Reply