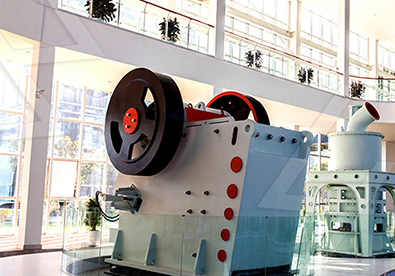

The Soda Feldspar PE Series Jaw Crusher Machine is a specialized crushing equipment designed for processing soda feldspar, a key raw material in ceramics, glass, and other industrial applications. Here’s a detailed breakdown of its features, working principles, and applications:

—

1. Key Features of PE Series Jaw Crusher for Soda Feldspar

1. Key Features of PE Series Jaw Crusher for Soda Feldspar

– High Crushing Efficiency: Optimized jaw plate design ensures effective crushing of hard and brittle materials like feldspar.

– Durable Construction: Made from high-quality materials (e.g., manganese steel) to withstand abrasion from feldspar’s hardness (~6 on the Mohs scale).

– Adjustable Discharge Size: Allows control over output particle size (typically 10–350 mm) for downstream processes.

– Low Energy Consumption: Efficient motor design reduces operational costs.

– Stable Performance: Robust structure minimizes vibration and noise.

—

2. Working Principle

2. Working Principle

– The motor drives the eccentric shaft, causing the movable jaw to move cyclically against the fixed jaw.

– Soda feldspar is fed into the crushing chamber and compressed between the jaws until it reaches the desired size.

– Crushed material exits through the discharge opening, adjustable via a wedge or hydraulic system.

—

3. Technical Specifications (Example: PE-600×900 Model)

| Parameter | Specification |

|——————|—————————-|

| Feed Opening | 600×900 mm |

| Max Feed Size | ≤500 mm |

| Discharge Range | 65–160 mm |

| Capacity | 50–180 t/h |

| Motor Power | 55–75 kW |

| Weight | ~15.5 tons |

*(Note: Customizable based on production needs.)*

—

4. Applications

– Ceramics Industry: Crushing soda feldspar for use in glazes and porcelain.

– Glass Manufacturing: Producing uniform feldspar granules to act as a flux.

– Abrasive & Paint Industries: Fine grinding for fillers or coatings.

—

5. Advantages Over Other Crushers

– Jaw Crusher vs. Hammer Crusher:

– Jaw crushers offer better particle shape control (less over-crushing).

– Lower wear rates due to fewer collisions compared to hammer mills.

– Jaw Crusher vs. Roll

Leave a Reply