The Crusher Phosphate Plant refers to a facility involved in the primary crushing of phosphate rock, which is a key step in the production of phosphate fertilizers and other phosphate-based products. Here’s an overview of its function, components, and importance:

1. Purpose of a Crusher in a Phosphate Plant

1. Purpose of a Crusher in a Phosphate Plant

– Size Reduction: Phosphate rock mined from deposits is typically large and uneven. The crusher breaks it down into smaller, manageable pieces for further processing.

– Beneficiation Preparation: Crushed phosphate rock is easier to wash, screen, d separate from impurities before chemical processing.

d separate from impurities before chemical processing.

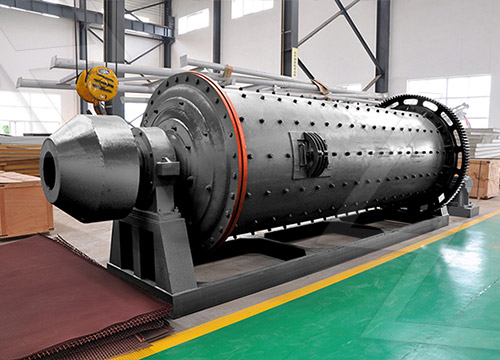

2. Types of Crushers Used

Common crushers in phosphate plants include:

– Jaw Crusher: Primary crushing for large rocks.

– Impact Crusher / Hammer Mill: Secondary crushing for finer particles.

– Roll Crusher: Used for medium-hard phosphate rock.

– Cone Crusher: For high-capacity fine crushing.

3. Key Components of a Phosphate Crushing Plant

– Feed Hopper: Receives raw phosphate ore.

– Vibrating Grizzly Feeder: Removes fine material before crushing.

– Primary & Secondary Crushers: Reduce rock size in stages.

– Screens & Classifiers: Separate crushed material by size.

– Conveyor Belts: Transport crushed rock to storage or beneficiation units.

– Dust Control Systems (Bag Filters/Wet Scrubbers): Minimize environmental impact.

4. Beneficiation After Crushing

After crushing, phosphate rock undergoes:

– Washing & Screening (removes clay/sand).

– Flotation (separates phosphate from silica/impurities).

– Drying & Grinding (prepares for acidulation in fertilizer production).

5. Challenges in Phosphate Crushing

– Abrasive Nature of Rock: Causes wear on crusher parts (requires frequent maintenance).

– Moisture Content: Can lead to clogging; pre-drying may be needed.

– Dust Generation: Requires strict air pollution controls.

6. Global Context

Major phosphate producers (Morocco, China, USA) use advanced crushing plants to meet fertilizer demand. Sustainable practices like water recycling and dust suppression are increasingly important.

Would you like details on specific equipment suppliers or operational best practices?

Leave a Reply