Ceramic liners for ball mills are specialized components designed to protect the mill shell from wear and abrasion while also improving grinding efficiency. They are commonly used in industries like mining, ceramics, cement, and chemicals, where abrasive materials are processed. Here’s a detailed overview:

Key Features of Ceramic Liners for Ball Mills:

Key Features of Ceramic Liners for Ball Mills:

1. Material Composition

– Made from high-alumina ceramics (e.g., 92% or 95% Al₂O₃) or zirconia for extreme wear resistance.

– Some liners may include rubber-ceramic composites for impact absorption.

2. Advantages

– Wear Resistance: Far superior to steel liners in abrasive environments.

– Corrosion Resistance: Ideal for wet grinding or chemically aggressive slurries.

– Reduced Contamination: Ceramic liners minimize metal contamination in sensitive processes (e.g., ceramics, pigments).

– Energy Efficiency: Smoother surface reduces friction, potentially lowering energy consumption.

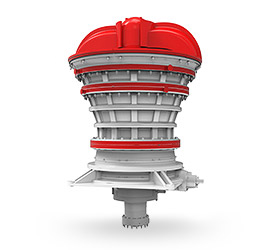

3. Design Types

– Flat Tiles: Simple rectangular or trapezoidal plates bolted to the mill shell.

– Lifter Bars: Designed to enhance grinding efficiency by lifting grinding media.

– Composite Liners: Combine ceramic with rubber or polyurethane for impact resistance.

4. Applications

– Mining: Grinding ores like gold, copper, and iron.

– Ceramics/Paints: Avoiding metal contamination in fine grinding.

– Cement: Used in raw meal or clinker grinding.

Installation & Maintenance Considerations

Installation & Maintenance Considerations

– Proper Fitting: Requires precise alignment to avoid cracking under stress.

– Impact Sensitivity: Pure ceramic liners may chip under heavy impact; composite designs are better for high-impact mills.

– Replacement: Longer lifespan than steel but more brittle—monitor for cracks.

Comparison with Other Liners

| Liner Type | Pros | Cons |

|—————|———|———|

| Ceramic | High wear resistance, low contamination | Brittle, higher upfront cost |

| Steel | Impact-resistant, cheaper | Wears faster, contaminates product |

| Rubber | Shock-absorbing, quiet | Lower wear resistance in abrasive slurries |

Manufacturers & Suppliers

–

Leave a Reply