Pulverized aluminum (Al) ring and ball mills are specialized grinding equipment used to reduce aluminum or aluminum-based materials into fine powders. These mills are commonly used in industries such as metallurgy, pyrotechnics, aerospace, and additive manufacturing (e.g., powder bed fusion).

Key Features of Ring and Ball Mills for Aluminum Pulverization:

Key Features of Ring and Ball Mills for Aluminum Pulverization:

1. Grinding Mechanism:

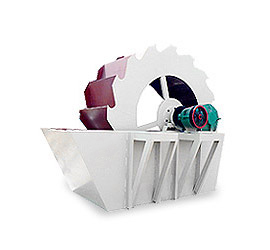

– Ring and Ball Mills (a type of vertical spindle mill) use grinding balls or rollers that crush the material between a rotating ring and stationary balls/rollers.

– Aluminum is fed into the mill, where it is crushed, ground, and pulverized into fine particles.

2. Applications of Pulverized Aluminum:

– Pyrotechnics & Explosives: Used in flash powders, thermite mixtures, and solid rocket fuels.

– Additive Manufacturing (3D Printing): Fine aluminum powder is used in selective laser sintering (SLS) or binder jetting.

– Metallurgy: For alloy production or powder metallurgy.

– Paints & Coatings: As a pigment or reflective additive.

3. Safety Considerations:

– Aluminum powder is highly combustible, especially in fine form (<50 µm). Milling must be done under inert atmospheres (e.g., nitrogen or argon) to prevent explosions.

– Anti-static measures and explosion-proof equipment are essential.

4. Types of Mills Used for Aluminum Pulverization:

– Ball Mills: Tumbling mills with steel/ceramic balls; suitable for wet/dry grinding.

– Ring-Roller Mills (Vertical Spindle Mills): More efficient for fine grinding.

– Attrition Mills: For ultrafine aluminum powders (<10 µm).

– Jet Mills (Fluid Energy Mills): For very fine powders without contamination.

5. Challenges in Aluminum Milling:

– Cold welding (due to ductility).

– Oxidation risk (can be minimized th inert gas).

th inert gas).

– Heat generation requiring cooling systems.

Best Practices for Pulverizing Aluminum:

– Use inert gas (N₂/Ar) to prevent oxidation/explosion.

– Control particle size distribution via milling time & ball size.

– Avoid excessive heat buildup to prevent agglomeration.

– Post-milling sieving/classification for uniform particle size.

Would you like details on a specific type of mill or safety protocol?

Leave a Reply