# Project Report: Gold Mining Machine

## 1. Introduction

Gold mining is a crucial industry for extracting precious metals used in jewelry, electronics, and investment. This project report outlines the development and implementation of a gold mining machine, detailing its design, operation, cost analysis, and environmental impact.

—

## 2. Objectives

– Develop an efficient gold mining machine for small to medium-scale operations.

– Ensure cost-effectiveness while maintaining high recovery rates.

– Minimize environmental impact through sustainable practices.

– Comply with safety and regulatory standards.

—

## 3. Machine Specifications

3.1. Types of Gold Mining Machines

3.1. Types of Gold Mining Machines

1. Trommel Screens – Used for alluvial gold separation.

2. Shaking Tables – Gravity-based separation for fine gold particles.

3. Centrifugal Concentrators (Knelson/Falcon) – High-G force separation.

4. Jig Machines – Effective for coarse gold recovery.

5. Cyanidation Leaching Plants – Chemical extraction for high-grade ores.

Cyanidation Leaching Plants – Chemical extraction for high-grade ores.

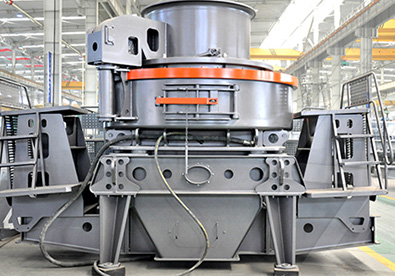

3.2. Proposed Machine Design

– Type: Hybrid Trommel + Centrifugal Concentrator

– Capacity: 5–10 tons/hour

– Power Source: Diesel/Electric motor (15–30 HP)

– Material Recovery Rate: 90–95%

—

## 4. Working Principle

1. Feeding System: Raw ore is fed into the trommel for initial screening.

2. Washing & Scrubbing: Removes clay and debris.

3. Gravity Separation: Gold particles are concentrated using centrifugal force.

4. Final Refinement: Gold concentrate is further processed via sluice or mercury-free methods.

—

## 5. Cost Analysis

| Component | Estimated Cost (USD) |

|———–|———————-|

| Trommel Screen | $8,000 – $15,000 |

| Centrifugal Concentrator | $12,000 – $25,000 |

| Pump & Piping System | $3,000 – $7,000 |

| Structural Frame | $5,000 – $10,000 |

| Labor & Installation | $7,000 – $12,000 |

| Miscellaneous (Transport, Permits) | $5,000 – $8,000 |

| Total Estimated Cost | $40,000 – $77,000 |

—

## 6. Environmental & Safety Considerations

✅ Water recycling system

Leave a Reply