Iron ore dressing (beneficiation) processing plants aim to improve the economic value of iron ore by removing impurities and increasing iron content. Here are the key guidelines for designing and operating an efficient iron ore dressing plant:

1. Ore Characterization

– Conduct thorough geological and mineralogical studies to understand ore composition (hematite, magnetite, goethite, etc.).

– Perform size analysis, chemical assays, and liberation studies to determine optimal processing routes.

2. Crushing & Screening

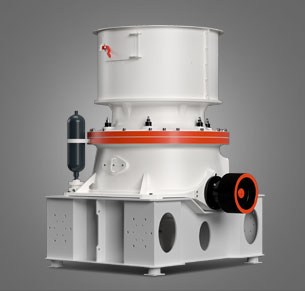

– Use a three-stage crushing system (primary, secondary, tertiary) for efficient size reduction.

– Employ vibrating screens to classify ore into different size fractions.

– Aim for a feed size suitable for downstream grinding (typically <25mm).

3. Grinding & Classification

3. Grinding & Classification

– Use ball mills, rod mills, or autogenous grinding (AG/SAG mills) based on ore hardness.

– Ensure proper classification using hydrocyclones or spiral classifiers to avoid over-grinding.

– Target a grind size that maximizes liberation of iron minerals (~45–150 microns).

4. Beneficiation Techniques

# (a) Magnetic Separation (for magnetite ores)

– Use low-intensity magnetic separators (LIMS) for coarse particles.

– Apply high-intensity magnetic separators (.jpg) S) or wet high-intensity magnetic separation (WHIMS) for fine particles.

S) or wet high-intensity magnetic separation (WHIMS) for fine particles.

# (b) Gravity Separation (for hematite/goethite ores)

– Utilize spiral concentrators, jigs, or shaking tables for coarse-to-medium particles.

– Apply multi-gravity separators (MGS) for fine particles.

# (c) Flotation (for silica/phosphorus removal)

– Use reverse flotation with anionic/cationic collectors to remove silica or phosphorous.

– Optimize pH, reagent dosage, and froth stability.

# (d) Scrubbing & Desliming

– Remove clay and ultrafines (<10µm) via attrition scrubbers and hydrocyclones.

5. Dewatering & Tailings Management

– Use thickeners for water recovery.

– Apply vacuum filters or pressure filters for final concentrate dewatering.

– Implement a sustainable tailings storage facility (dry stacking or paste disposal) to minimize environmental impact.

6. Product Quality Control

– Maintain

Leave a Reply