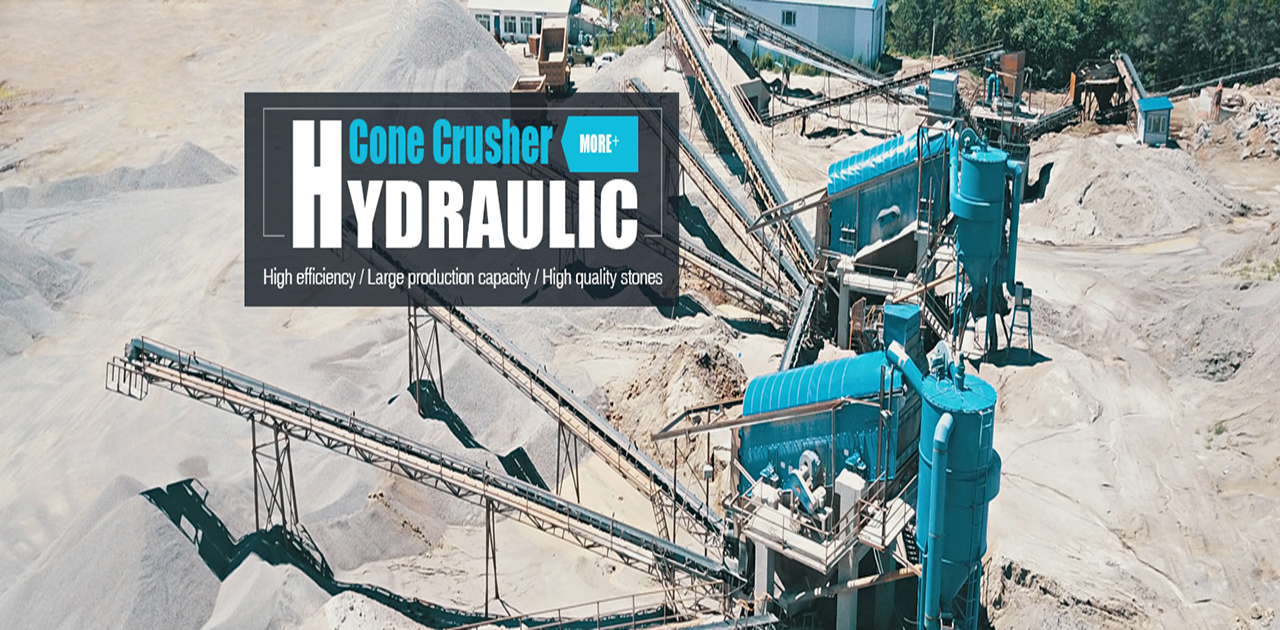

The cost of setting up a gravel crusher plant (TPH – Tons Per Hour) depends on several factors, including plant capacity, equipment selection, site conditions, and regional labor/material costs. Below is a general breakdown:

.jpg) Key Cost Factors for a Gravel Crusher Plant (50-300 TPH)

Key Cost Factors for a Gravel Crusher Plant (50-300 TPH)

1. Plant Capacity (TPH)

– Small-scale (50-100 TPH): Lower initial investment

– Medium-scale (150-250 TPH): Balanced cost & efficiency

– Large-scale (300+ TPH): Higher upfront cost but better ROI

2. Equipment Costs

– Primary Crusher (Jaw/Gyratory): $50,000–$500,000+

– Secondary Crusher (Cone/Impact): $60,000–$400,000

– Vibrating Screens: $20,000–$150,000

– Conveyors & Feeders: $10,000–$100,000

– Control System & Electricals: $30,000–$150,000

3. Site Preparation & Civil Work

– Land clearing, foundation work: $20,000–$200,000

– Permits & environmental compliance: $5,000–$50,000

4. Labor & Installation

– Assembly & commissioning: $30,000–$150,000

5. Operating Costs

– Fuel/Power: ~$5–15 per ton crushed

– Maintenance: ~10-20% of initial cost annually

Estimated Total Cost Range

Estimated Total Cost Range

| Plant Capacity (TPH) | Approximate Cost Range |

|———————-|———————–|

| 50-100 TPH | $200,000 – $500,000 |

| 150-250 TPH | $500,000 – $1.2M |

| 300+ TPH | $1M – $3M+ |

Additional Considerations

– Mobile vs. Stationary Plant: Mobile crushers (~15-30% more expensive) offer flexibility but higher per-ton costs.

– Material Hardness: Harder rocks require more robust (expensive) crushers.

– Location: Remote sites increase logistics costs.

– Automation: Higher upfront cost but reduces long-term labor expenses.

Would you like a detailed breakdown for a specific

Leave a Reply