An iron ore crushing and screening plant is a facility designed to process raw iron ore into smaller, more manageable sizes for further beneficiation or direct shipping. Here’s a breakdown of its key components and processes:

—

1. Crushing Stages

1. Crushing Stages

Iron ore is typically hard and abrasive, requiring robust crushing equipment:

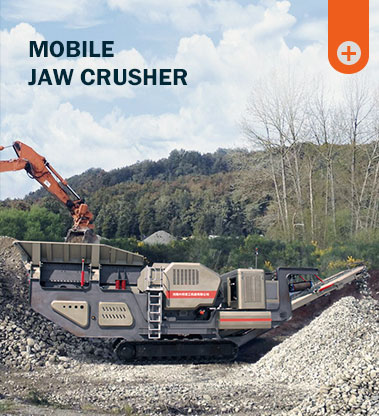

– Primary Crushing:

– Uses jaw crushers or gyratory crushers to reduce large lumps (up to 1.5m) to ~150–250mm.

– High-capacity and rugged design to handle abrasive ore.

– Secondary & Tertiary Crushing:

– Cone crushers or impact crushers further reduce size to ~10–30mm.

– May include a closed-circuit system with screens for recirculating oversized material.

—

2. Screening Process

Screens separate crushed ore into specific size fractions:

– Vibrating Screens:

– Classify ore into sizes (e.g., lump ore, fines, or pellets feed).

– Common screen types: banana screens, horizontal screens, or high-frequency screens.

– Scalping Screens:

– Remove undersized material before crushing to improve efficiency.

—

3. Key Equipment

– Crushers: Jaw, gyratory, cone, or HPGR (High-Pressure Grinding Rolls).

– Screens: Multi-deck vibrating screens for precise sizing.

– Conveyors: Belt conveyors transport ore between stages.

– Dust Control Systems: Bag filters or water sprays to suppress dust.

—

4. Flow Diagram Example

1. Run-of-Mine (ROM) Ore → Primary Crusher → Coarse Screening (+150mm recirculated).

2. Secondary Crusher → Fine Screening (e.g., 10–30mm for beneficiation).

3. Fines (<10 may bypass crushing for direct processing (e.g., pelletizing).

may bypass crushing for direct processing (e.g., pelletizing).

—

5. Design Considerations

– Ore Characteristics: Hardness (e.g., hematite vs. magnetite), moisture content, and abrasiveness influence equipment choice.

– Capacity: Ranges from 500 TPH (small plants) to >10,000 TPH (large-scale operations).

– Automation: Modern plants use PLC systems for real-time monitoring and optimization.

—

6. Applications

–

Leave a Reply