Soapstone Crushing and Milling Equipment Guide

Soapstone (also known as steatite) is a soft metamorphic rock composed mainly of talc, making it easy to process. Crushing and milling soapstone requires specialized equipment to achieve the desired fineness for applications like cosmetics, ceramics, paints, and carving.

1. Crushing Equipment for Soapstone

1. Crushing Equipment for Soapstone

Since soapstone is relatively soft, primary crushing can be done with:

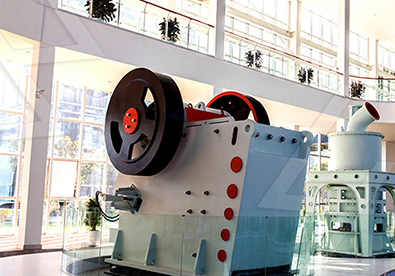

– Jaw Crusher: For coarse crushing (reducing large chunks to smaller pieces).

– Hammer Crusher / Impact Crusher: Efficient for medium-sized soapstone rocks

– Roll Crusher: Suitable for fine crushing with minimal dust generation.

2. Milling/Grinding Equipment for Soapstone Powder

After crushing, soapstone is ground into fine powder using:

– Raymond Mill (Vertical Roller Mill): Produces 80–400 mesh powder, ideal for industrial uses like paint and coatings.

– Ball Mill: For ultra-fine grinding (up to 800 mesh or finer), used in cosmetics and pharmaceuticals.

– Ultrafine Grinding Mill (HGM Series): Produces 325–2500 mesh powder for high-end applications like talcum powder.

3. Auxiliary Equipment

– Vibrating Feeder & Screener: Ensures uniform feeding and particle size control.

– Dust Collector (Pulse Jet Bag Filter): Prevents talc dust pollution during processing.

– Packaging Machine: For filling powdered soapstone into bags or containers.

Key Considerations

– Soapstone is soft; avoid excessive heat generation during milling to preserve quality.

– Moisture content should be controlled (<1%) for ultrafine grinding.

– Talc's lubricity may require specialized liners in milling equipment to reduce wear.

Would you like recommendations based on production capacity or specific end-use? Let me know your requirements!