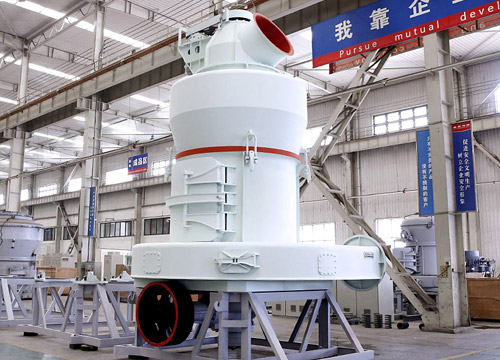

A grinding mine mill machine is a type of industrial equipment used in mining and mineral processing to reduce the size of ore particles, liberate valuable minerals from waste rock, and prepare materials for further processing. These machines are crucial in the beneficiation process, ensuring efficient extraction of metals like gold, copper, iron, and others.

Types of Grinding Mill Machines Used in Mining:

Types of Grinding Mill Machines Used in Mining:

1. Ball Mill

– Uses steel balls as grinding media.

– Suitable for wet or dry grinding.

– Commonly used for fine grinding in mineral processing.

2. Rod Mill

– Uses long steel rods instead of balls for grinding.

– Produces a coarser product than ball mills.

– Often used in the first stage of grinding.

3. SAG Mill (Semi-Autogenous Grinding Mill)

– Uses a combination of ore and grinding balls (partially autogenous).

– Handles large feed sizes and reduces material before secondary grinding.

4. AG Mill (Autogenous Grinding Mill)

– Relies solely on the ore itself as grinding media (no steel balls).

– Used when ore is competent enough to grind itself.

5. Vertimill® (Vertical Grinding Mill)

– Energy-efficient alternative to ball mills.

– Uses gravity and a screw mechanism for grinding.

6. HPGR (High-Pressure Grinding Rolls)

– Applies extreme pressure to crush ore between two rollers.

– Energy-efficient with lower water consumption compared to traditional mills.

7. Stirred Mill (e.g., IsaMill, TowerMill)

– Uses agitators to enhance fine and ultra-fine grinding.

– Common in regrinding applications for precious metals like gold and platinum.

Key Components of a Grinding Mine Mill:

– Grinding Media (balls, rods, or ore itself)

– Liners (protect the mill shell from wear)

– Drive System (motor, gearbox/pinion)

– Feed & Discharge Mechanisms (spiral classifier, hydrocyclone)

Applications in Mining:

Applications in Mining:

– Ore comminution (size reduction) before flotation or leaching.

– Preparing feed for downstream processes like smelting or refining.

– Producing finely ground material for tailings disposal or further processing