Milling ore for gold mining involves several steps to break down the ore and extract the gold. Here’s a general process:

1. Crushing the Ore

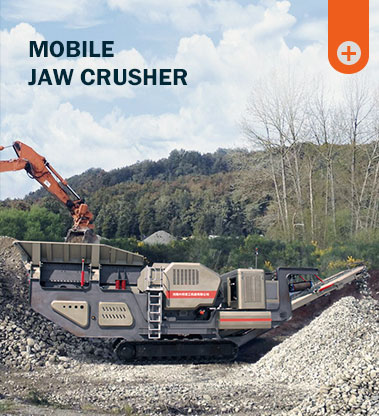

– Primary Crushing: Use a jaw crusher or gyratory crusher to reduce large chunks of ore into smaller pieces (~6 inches or smaller).

– Secondary Crushing: Further crush the ore using a cone crusher or impact crusher to achieve finer particles (~1 inch or smaller).

2. Grinding (Milling) the Ore

– Ball Mill or Rod Mill: The crushed ore is fed into a rotating mill with steel balls or rods to grind it into a fine powder (typically 100-200 mesh). Water is often added to create a slurry.

– SAG Mill (Semi-Autogenous Grinding): Some operations use large rotating drums where ore and grinding media break down the material.

3. Classification (Sizing)

– A spiral classifier or hydrocyclone separates the ground material into coarse and fine fractions, ensuring proper particle size for gold recovery.

4. Gold Extraction Methods

# A. Gravity Separation (For Free-Milling Gold)

# A. Gravity Separation (For Free-Milling Gold)

– Shaking Tables, Sluices, or Centrifuges: Used to separate gold from lighter materials based on density.

# B. Froth Flotation (For Sulfide Ores)

– Chemicals are added to make gold-bearing minerals hydrophobic, allowing them to attach to air bubbles and float for collection.

# C. Cyanidation (Most Common for Fine Gold)

# C. Cyanidation (Most Common for Fine Gold)

– The finely ground slurry is mixed with a weak cyanide solution (NaCN or KCN), which dissolves the gold.

– The gold-laden solution is then processed through:

– Carbon-in-Pulp (CIP): Activated carbon adsorbs gold from the cyanide solution.

– Carbon-in-Leach (CIL): Similar to CIP but with leaching and adsorption happening simultaneously.

– Merill-Crowe Process: Zinc dust precipitates gold from the cyanide solution.

# D. Heap Leaching (For Low-Grade Ores)

– Crushed ore is piled on a lined pad and irrigated with cyanide solution, which percolates through and dissolves gold.

5. Refining & Smelting

– The collected gold concentrate is further refined by:

– Smelting in a furnace with fluxes to remove impurities.