The production process flow of Messebo Cement Factory (located in Ethiopia) follows the dry process method, which is energy-efficient and commonly used in modern cement plants. Below is a step-by-step breakdown of the cement manufacturing process at Messebo:

—

1. Raw Material Extraction & Preparation

– Quarrying: Limestone (primary raw material), clay, shale, gypsum, and other additives are mined from the quarry.

– Crushing & Pre-homogenization:

– Raw materials are crushed into smaller pieces (using crushers).

– Stockpiled and homogenized to ensure consistent chemical composition.

.jpg) 2. Raw Meal Grinding (Raw Mill)

2. Raw Meal Grinding (Raw Mill)

– Crushed raw materials are ground into a fine powder in a vertical roller mill (VRM) or ball mill.

– A homogenizing silo ensures uniform blending before kiln feeding.

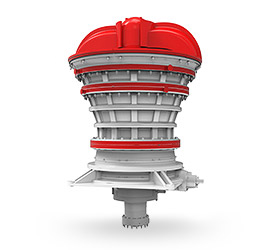

3. Preheating & Pre-calcination (Preheater Tower & Calciner)

– The raw meal passes through a 4-6 stage preheater cyclone tower, where hot gases from the kiln heat it to ~900°C.

– In the calciner, ~90% of limestone (CaCO₃) decomposes into lime (CaO) and CO₂ before entering the kiln.

4. Clinker Production (Rotary Kiln)

– The preheated meal enters a long, rotating kiln (~1450°C).

– Chemi reactions form clinker (small, dark gray nodules) through sintering.

reactions form clinker (small, dark gray nodules) through sintering.

5. Clinker Cooling (Grate Cooler)

– Hot clinker exits the kiln and is rapidly cooled in a grate cooler.

– Recovered heat is reused in the kiln/preheater for efficiency.

6. Cement Grinding (Cement Mill)

– Clinker is mixed with gypsum (~5%) and additives (e.g., pozzolana, slag).

– Ground into fine powder in a ball mill or vertical roller mill to produce cement:

– OPC (Ordinary Portland Cement)

– PPC (Portland Pozzolana Cement)

7. Storage & Packing

– Cement is stored in silos for quality control before dispatch.

– Packaged in bags (~50kg) or loaded as bulk for transport