The grinding process in gold mining is a critical step that involves reducing the size of the ore to liberate the gold particles for further processing. Here’s an overview of the grinding process and the types of machines commonly used:

.jpg) Grinding Process in Gold Mining

Grinding Process in Gold Mining

1. Crushing: Before grinding, the ore is typically crushed into smaller pieces using crushers (e.g., jaw crushers, cone crushers).

2. Grinding: The crushed ore is then fed into grinding mills to further reduce its size. The goal is to achieve a fine powder that allows for efficient gold extraction.

3. Liberation: Grinding helps liberate gold particles from the surrounding rock or mineral matrix.

4. Separation: After grinding, the material is processed through methods like cyanidation, flotation, or gravity separation to extract the gold.

—

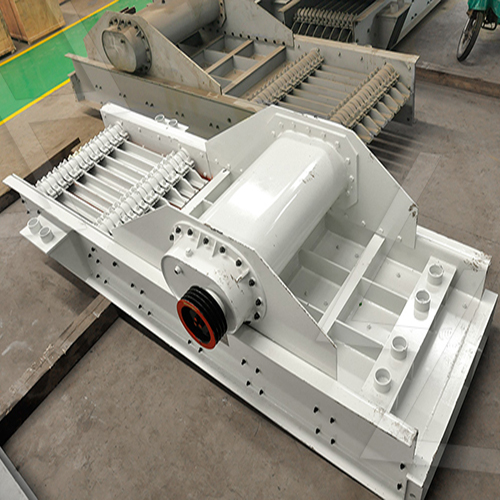

Machines Used in Grinding Process

1. Ball Mills:

– Most commonly used in gold mining.

– Consist of a rotating cylinder filled with steel balls that grind the ore as the cylinder rotates.

– Suitable for both wet and dry grinding.

2. SAG Mills (Semi-Autogenous Grinding Mills):

– Use a combination of ore and steel balls for grinding.

– Often used in large-scale mining operations.

– Efficient for coarse grinding.

3. Rod Mills:

– Use long steel rods instead of balls for grinding.

– Ideal for finer grinding and less prone to over-grinding.

4. Vertical Roller Mills:

– Used for fine grinding of ore.

– Energy-efficient compared to traditional ball mills.

5. Stirred Mills (e.g., IsaMill):

– High-intensity grinding machines used for ultrafine grinding.

– S able for refractory ores where fine liberation is required.

able for refractory ores where fine liberation is required.

—

Key Considerations

– Particle Size: The optimal particle size depends on the type of gold ore and extraction method.

– Energy Efficiency: Grinding is energy-intensive, so selecting efficient equipment is crucial.

– Wear and Tear: Grinding media (balls, rods) and mill liners are subject to wear and need regular maintenance.

– Water Usage: Wet grinding requires water, which must be managed in arid regions.

—

Post-Grinding Processes

After grinding, the slurry (a mixture of ground ore and water) is processed through:

– Cyanidation: Dissolving gold using cyanide solution.

–