Creating an effective mineral ball mill plant involves several key considerations to ensure optimal performance, efficiency, and longevity. Below are the essential steps and factors to consider:

—

1. Plant Design and Layout

– Site Selection: Choose a location with adequate space, access to raw materials, and proximity to transportation routes.

– Flow Sheet Design: Develop a detailed process flow sheet that includes crushing, grinding, classification, and separation stages.

– Equipment Placement: Optimize the layout for efficient material flow, minimizing bottlenecks and ensuring easy maintenance access.

—

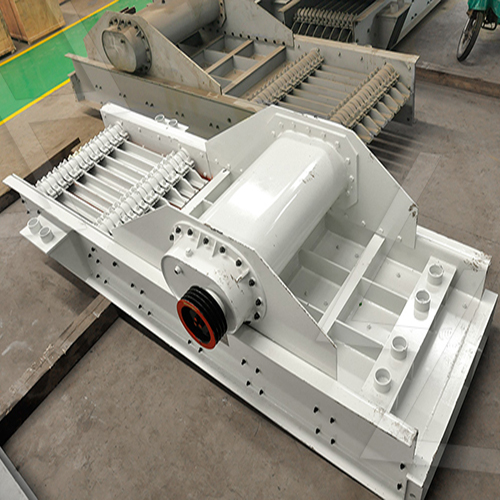

2. Ball Mill Selection

– Type of Ball Mill: Choose the appropriate type (e.g., overflow ball mill, grate discharge ball mill) based on the mineral characteristics and desired output.

– Size and Capacity: Select a ball mill with the right dimensions and capacity to handle the required throughput.

– Liner Material: Use durable liners (e.g., rubber, steel, or ceramic) to reduce wear and extend the mill’s lifespan.

—

3. Grinding Media

– Material: Use high-quality grinding media (e.g., steel balls, ceramic balls) suited to the mineral being processed.

– Size Distribution: Optimize the size of grinding media for efficient particle size reduction.

– Replacement Strategy: Regularly monitor media wear and replace as needed to maintain grinding efficiency.

—

4. Feed Preparation

4. Feed Preparation

– Crushing: Ensure proper crushing of raw materials to achieve a consistent feed size for the ball mill.

– Moisture Control: Manage moisture levels in the feed to prevent issues like slurry viscosity or clogging.

—

5. Classification System

– Cyclones or Screens: Install an efficient classification system (e.g., hydrocyclones) to separate fine particles from coarse ones for recirculation.

– Closed-Circuit Grinding: Implement a closed-circuit system to improve grinding efficiency and control product size.

—

6. Automation and Control

– Process Control Systems: Use advanced control systems (e.g., PLCs or DCS) to monitor and optimize mill operation.

– Sensors and Instrumentation: Install sensors for real-time monitoring of parameter.jpg) ike feed rate, power consumption, and particle size.

ike feed rate, power consumption, and particle size.

—

7. Energy Efficiency

– Variable Speed Drives: Use variable frequency drives (VFDs) to optimize motor speed and reduce energy consumption.

– Heat Recovery: Implement heat recovery systems if applicable to reduce energy waste.

—

8.