Cone crusher is used for two-stage crushing and three-stage crushing in metal mining and construction sand and gravel processing. It has a large crushing ratio, high crushing efficiency, low wear of wearing parts, uniform product particle size, and grade coordination. It is suitable for medium and fine crushing of various ores and rocks with a Platts hardness of less than 16, such as iron ore, non-ferrous metal ore, granite, basalt, quartz stone, pebbles, sandstone, limestone, etc.So, what about the cone crusher of Liming Heavy Industry?Next, I will take the bosses to understand in detail.

Development history of cone crusher

At the end of the 19th century, the Simmons Brothers in the United States developed a spring-type cone crusher.

In 1940, the American Allis Chalmers Company launched a bottom single-cylinder hydraulic cone crusher.

In 1970, Shen Shengsheng produced the first domestic single-cylinder cone breaker.

In 1990, the United States Nordberg Company launched a new generation of HP series cone crusher.

Since its establishment in 1987, Liming Heavy Industry has continuously absorbed the scientific experience and market launch experience of upgrading the modernization of the industry, and relying on the 1.2 million-square-meter production base of the entire industrial chain, it has been continuously committed to the research and development and intelligent manufacturing of crushing and screening equipment.For more than 30 years, the original intention of spring and autumn has not changed. The cone crusher series products that Liming Heavy Industry has launched now mainly include CS series spring cone crusher, HST series single-cylinder hydraulic cone crusher and HPT series multi-cylinder hydraulic cone crusher. Among them, the four models of HST250 (H/S), HST315 (H/S), HPT300 and HPT500 are highly favored by customers.

the product advantages of cone crusher

Cone crushers have spring cone breaking, hydraulic cone breaking, composite cone breaking and other types according to the different crushing principles.

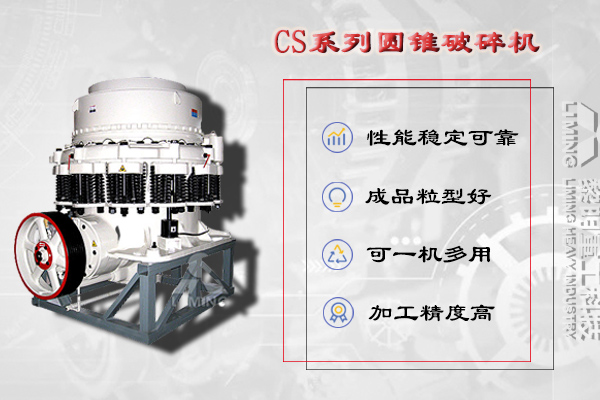

CS spring cone break

1. Optimize the organic combination of cavity shape, reasonable speed and stroke

2. A variety of cavity types are available to meet the needs of multi-material medium and fine particles

3. Laminated crushing design, high efficiency, high energy consumption, high fine-grained content

4. Hydraulic lubrication system, automatic control, simplified operation and operation and maintenance

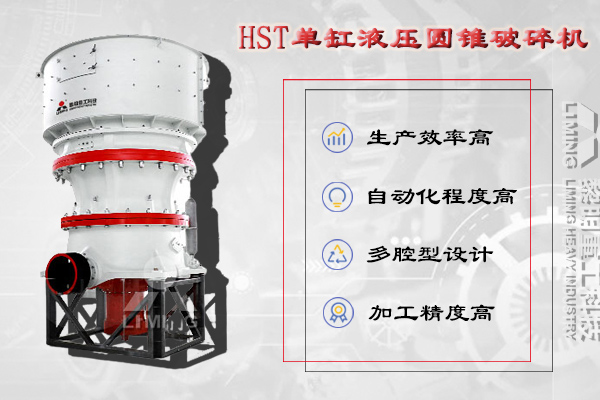

HST single-cylinder hydraulic cone breaker

1. The crushing cavity type, eccentricity and motion parameters are matched, and the quality is better

2. Fully automatic control system, automatic adjustment, give full play to the ideal performance of the equipment

3. Laminated crushing design, high efficiency, high energy consumption, high fine-grained content

4. The structure is simple, and all maintenance work can be completed after removing the upper rack

HPT multi-cylinder hydraulic cone breaking

1. PLC integrated control system, real-time understanding of equipment operation

2. The structure is optimized and upgraded, with stronger carrying capacity and greater installed power

3. Laminated crushing design, high efficiency, high energy consumption, high fine-grained content

4. Multi-cavity conversion, multi-purpose in one machine, to meet the needs of medium and fine crushing technology

If you are interested in our products or have any questions, please feel free to call us at any time whatsapp:+8613633818807 or click“< strong>Business Pass” For consultation, our customer service staff will provide you with detailed answers and thoughtful service. Your satisfaction will be our unremitting driving force for progress. You are welcome to click for consultation.

Cone crusher headquarters address: No.169, Science Avenue, High-tech Industrial Development Zone, Zhengzhou, China