The old saying is good, if you want to be rich, you must first build a road. In today’s socio-economic society, the highway is a modern road transportation channel that plays a vital role in the development of the economy.With the implementation of the national strategy of the “Belt and Road Initiative”, the expressway, as an exchange link and communication bridge connecting regional development and the world economy, will be further valued and strengthened by the country.So, how much do you know about highway mineral powder?Next, Xiaobian will take you to understand the production process and equipment recommendations of highway ore powder.

Introduction to highway mineral powder

Highway construction is inseparable from the support of a large amount of concrete, and adding other materials to the concrete material instead of cement can produce a new type of concrete with better performance, lower energy consumption and less environmental pollution.Mineral powder high-performance concrete is such a new type of green concrete. It uses materials such as limestone powder, industrial waste residue, blast furnace slag, etc., and is ground to a certain fineness. It can replace cement in large quantities (usually up to 30%-70% of the amount of cement) and is blended into concrete. It can not only regulate the performance of concrete, but also effectively reduce costs and realize the comprehensive utilization of resources. It is a green building material that is both sustainable and can obtain greater economic benefits.

The role of highway ore powder

The main chemical components of mineral powder are divided into CaO, SiO2, l2O3, Fe2O3, etc. The main roles in concrete are: reduce the amount of cement, improve the workability of concrete, reduce the heat of hydration, enhance the late strength, improve the internal structure of concrete, and improve the resistance to seepage and corrosion.rosion.After the concrete is incorporated into the finely ground ore powder, it can delay the hydration rate of the gelling material and prolong the condensation time of the concrete. This property is beneficial to the transportation and construction of concrete in the high temperature season.

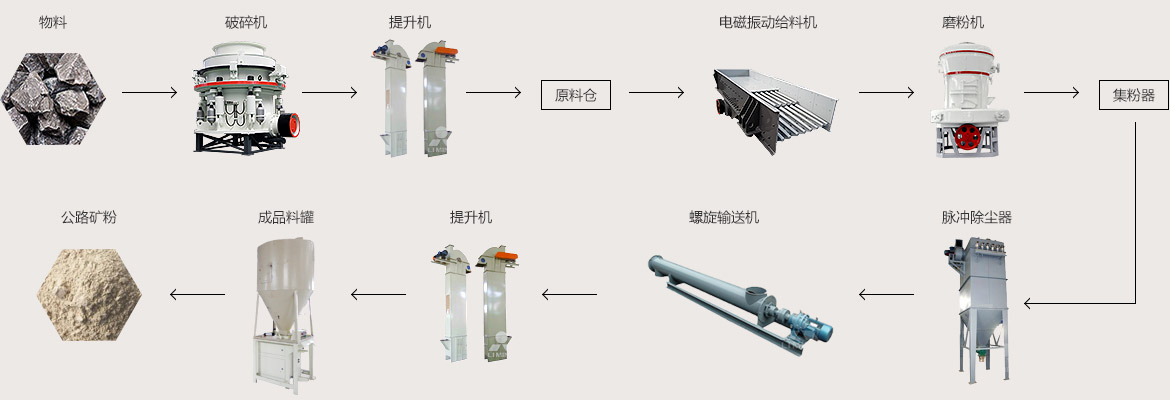

the production process of highway ore powder (detailed illustration)

After the large bulk material is broken by the crusher to the desired particle size, the material is sent to the silo by the hoist, and then the material is evenly and quantitatively continuously fed into the main grinding chamber by the vibrating feeder for grinding. The ground powder is taken away by the air flow of the fan and graded by the analysis machine. The powder that meets the fineness enters the large cyclone collector with the air flow, is separated and collected, and then discharged through the powder outlet tube to form the finished powder.

the selection of grinding equipment for highway ore powder

LM vertical mill —— Electronic control system using special milling device automation

[stand-alone output] 13-70T/H

【Outstanding advantages】

1. Product quality is stable. The product has a short residence time in the mill, it is easy to detect and control the particle size and chemical composition of the product, reduce repeated milling, and stabilize product quality.

2. High drying efficiency. The hot air that enters the mill from the outside can come into contact with the material multiple times and fully, and has a strong drying ability, which not only saves energy, but also meets the requirements of materials with different humidity.

3.Low operating cost. The grinding roller directly crushes and grinds the material on the grinding disc, and the energy consumption is low; the grinding roller and the grinding disc are not in direct contact during work, and the grinding roller and the liner are made of good quality materials, with long service life and less wear.

4. Environmentally friendly and clean. The vibration is low, the noise is low, and the equipment is sealed as a whole, the system works under negative pressure, there is no dust overflow, the environment is clean, and it meets the national environmental protection requirements.

5. The fineness of the finished powder is uniform , and the screening rate can reach more than 99%.

MTW series European version of the mill——Traditional Raymond mill, pendulum mill replacement replacement products

[stand-alone output] 13-70T/H

【Outstanding advantages】

1. Increased production capacity. Using grinding roller linkage booster technology, the output is increased by 20%; the bevel gear rotates as a whole, with less energy loss and high efficiency.

2. The technology is mature. The novel internal dilute oil lubrication system can realize bearing lubrication without additional oil pumps or lubrication stations; the curved air duct greatly improves the efficiency of the fan.

3.Low cost and low consumption. The system integrates crushing, drying, grinding, and grading and conveying. The layout is compact and the investment cost is low; the non-resistance air inlet volute and the same resistance arrangement scheme reduce system losses.

4. Human nature and environmental protection. The beautiful curved exterior design reduces the risk factor of manual operation and is more user-friendly; the air self-circulation system and dust collector carry out the concept of environmental protection to the end.

Liming Heavy Industry, a well-known overall solution provider of grinding equipment in the industry, has more than 30 years of experience in the production of grinding machines.Deepen the field of mineral blends.Can provide you with solutions for highway ore powder projects.If you are interested in our products or have any questions, please feel free to call us at any time whatsapp:+8613633818807 or click“ business Through ” For consultation, our customer service staff will provide you with detailed answers and thoughtful service. Your satisfaction will be our unremitting driving force for progress. You are welcome to click for consultation.

Highway ore powder grinding equipment headquarters Address: No.169, Science Avenue, High-tech Industrial Development Zone, Zhengzhou, China