Earlier, we talked about the selection of equipment for the pavement stone production line and the factors that need to be taken into account. Today we will talk about how to configure the pavement stone production line?And recommend a reliable production line configuration manufacturer for you.

How should the pavement stone production line be configured?

Usually, breaking stones into stones requires feeding, crushing, screening, conveying and other links. Different links correspond to one or more equipment. The following are described in detail.:

Feeding: The raw materials are fried from the mountains and stored in silos.The feeding stage is the stage where the vibrating feeder feeds the stones evenly and continuously into the crushing equipment.

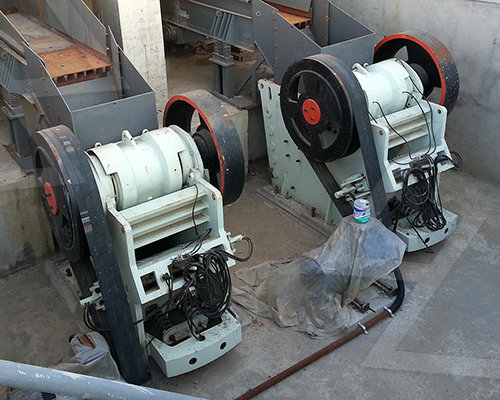

Crushing: This stage is mainly to realize the crushing and processing of stones. The stones will be turned into stones of various specifications that meet the material requirements through the action of the crusher.The commonly used equipment in the crushing stage is jaw crusher, impact crusher and cone crusher.

Screening: The main purpose of screening is to divide the gravel screen into the required finished product specifications and grades.Vibrating screen is the equipment used at this stage.

Conveying: The conveying link runs through the entire production process, and the belt conveyor is responsible for conveying the materials and finished products of each process.A stone production line usually needs to be equipped with multiple conveyor belts according to process requirements.

Pavement stone production line configuration plan

According to the different stone raw materials, the combination configuration operation can be carried out. In addition, many users also have certain requirements for the output of the stone production line. You can also configure it according to the construction output requirements. The following is the simple configuration plan made by Xiaobian for you.:

Plan 1: Vibrating feeder, jaw crusher, cone crusher, impact sand making machine, round vibrating screen, belt conveyor

Configuration characteristics: large crushing ratio, good particle size, high output, long service life, and low maintenance costs.

Plan 2: Vibrating feeder, jaw crusher, impact crusher, sand making machine, round vibrating screen, belt conveyor

Configuration characteristics: Compared with Scheme 1, it is more suitable for crushing soft materials and has a better particle size of the finished product. The initial investment cost of the overall configuration is low, and the later maintenance cost is high.

Pavement stone production line is recommended by reliable manufacturers

Here Xiaobian sincerely recommends Henan Liming Heavy Industry. It is a large-scale direct sales manufacturer. The factory produces independently and does not have any middlemen. All raw materials are directly supplied. Therefore, the price positioning of the production line equipment is not high. One unit faces customers at wholesale prices. Not only that, but what is more favorable is that all logistics are delivered to the door, the cost is relatively small, and it can save users a lot of transportation costs. The supporting manufacturing equipment is complete and the technology is proficient. On-site inspections make you more assured!We also provide customers with inspection services for the production line at the nearest construction site.