Construction stones are highly popular in the sand and gravel market. In order to make better use of construction stones and other stones, a crusher is often used to crush them so that construction stones can be fully utilized. What kind of crushing is used for construction stones? Stone machine? How much is a complete set of crushing equipment? The following article will introduce in detail;

What kind of stone crusher is used for building stones? Liming recommends several models for you

Taking the existing stone crusher production line equipment as an example, there are many types of stone crushers that can be used to crush construction stones, but considering the hardness characteristics of high construction stone materials and the convenience of production profits, these few A stone crusher for construction is more suitable!

(1) Jaw Crusher

Features: The jaw crusher is a kind of construction stone crusher with strong wear resistance. The materials of the accessories are all made of high-quality materials, such as high-strength steel, which improves the wear rate of the accessories and reduces the frequent replacement of accessories. Swing frequency, optimized cavity shape and reasonable stroke are integrated, equipped with an overload holding device. During work, when encountering materials to be crushed, foreign iron pieces can pass through the crushing cavity to reduce wear on the equipment. The crushing ratio is large, and the crushed The finished product of building stones and stones has a uniform particle size, which can meet the production needs;

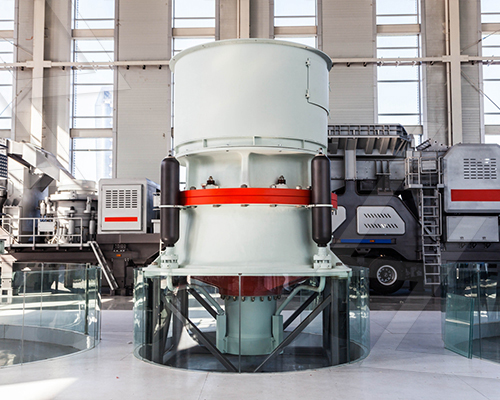

(2) Cone Crusher

Features: It is used for medium or fine crushing of building stones. At present, spring cone crushers, single-cylinder cone crushers, multi-cylinder cone crushers, etc. are commonly used. Laminated crushing has a large crushing ratio and good grain shape of the finished product; the overload protection device can Make the foreign matter and iron pieces pass through the crushing cavity without harming the machine; the cavity type can be changed arbitrarily to meet the requirements of a wide range of product particle sizes. In addition, the equipment is touch-screen operation + remote control, which is convenient and safe, and is very suitable for the crushing and processing of building stones;

(3) Impact stone crusher

Features: It is an equipment for finely crushing and sand-making processing of building stones. It can crush building stone particles with a feed size of 50mm to 1-5mm. The design of the deep cavity impeller can increase the throughput of building stones per unit time. Increased by about 30%; impact stone crusher is also called impact sand making machine, crushing VSI6X impact stone crusher and VSI impact stone crusher have many types and complete models, which can better meet the requirements of large, medium and small enterprises. Fine crushing demand for building stones;

How much does it cost to configure a complete set of equipment for building stone crushers?

The price of a complete set of building stone equipment can range from hundreds of thousands to one million, depending on the configuration of the output, the type and model of the equipment used, etc.; a complete set of building stones The processing equipment can be configured as a set of construction stone crushing production line, construction stone sand production line, etc., and the output can be configured to produce 100-1000 tons per hour, etc.; generally, a complete set of equipment configurations are 100t/h, 200t/h, 300t/h, 500t/h, etc.;

If you are interested in or have questions about our products, please call us at +86 15538087625 or click “Business Connect” for consultation at any time. Our customer service personnel will provide you with detailed answers and considerate services. Your satisfaction will be our unremitting driving force. You are welcome to click for consultation.