Typical lithium ore is divided into lithium pyroxene, perovskite feldspar, lithium mica and so on. With the development of science and technology, the era of progress, the rise of new energy industry, which makes some rare resources are reused, including lithium ore, then, how is lithium ore processing? What equipment do you need to use?

A. How is lithium ore processed?

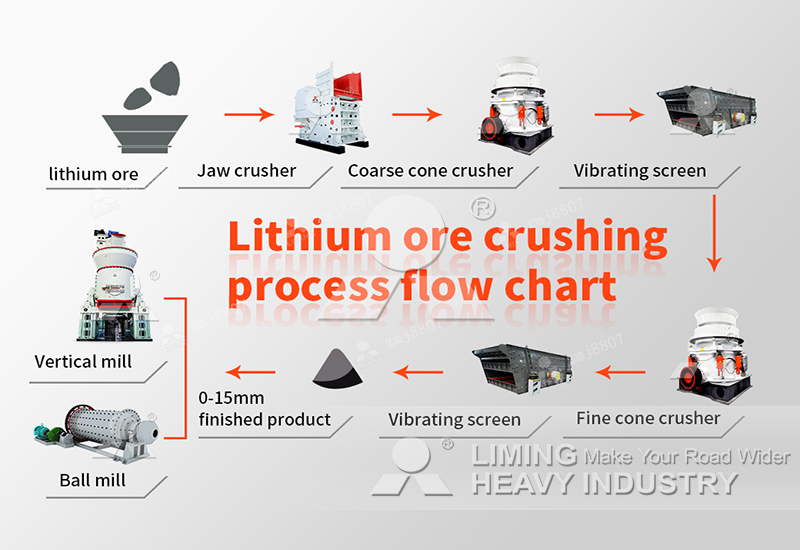

Lithium ore generally needs to be crushed – grinding – flotation and some auxiliary equipment processing to get finished products, the specific processing process is: lithium ore into the jaw crusher for coarse crushing materials and then by the cone crusher for the second crushing, and then into the vibrating screen for screening. Those that meet the standard size will enter the next process, those that do not will enter the cone crusher again for the second fine crushing, and the product will be sieved again after the second crushing to get the finished product of 0-15mm. After the sieving, the product will be ground by the vertical mill, so that you can get 100-200 purpose finished products.

B.what equipment is needed for lithium ore processing?

Coarse crushing-jaw crusher

It uses domestic and foreign famous brand supporting parts, such as bearings, motors, etc. The quality is guaranteed and can meet the user’s demand for different configurations. The equipment structure, function and production efficiency all reflect the modern advanced technology level, which solves the problems of low production efficiency and difficult installation and maintenance of existing jaw crushers in the market, and is the ideal coarse crushing equipment.

Fine Crushing – Cone Crusher

Based on the traditional cone crusher with fixed main shaft, eccentric sleeve rotating around the main shaft and laminated crushing principle, the structure has been optimized to significantly improve the performance and crushing capacity of the equipment; and the hydraulic lubrication system is designed to ensure smarter and more reliable operation of the equipment.

Grinding – Vertical Mill

With compact and integrated design, the floor space is about 50% of the ball mill system, and it can be arranged in the open air, so the comprehensive investment is less. And it can effectively control the product size, chemical composition and iron content of the product to ensure the purity and whiteness of the finished material. With automatic control system, remote control and local control can be freely switched, easy to operate and low labor cost. The whole sealed and working under negative pressure, no dust overflow; equipment vibration is small, low noise operation; production operation is more environmentally friendly.

The above is the recommendation of lithium ore processing and the equipment used.If you are interested in or have questions about our products, please call us or click “Business Connect” for consultation at any time. Our customer service personnel will provide you with detailed answers and considerate services. Your satisfaction will be our unremitting driving force. You are welcome to click for consultation.