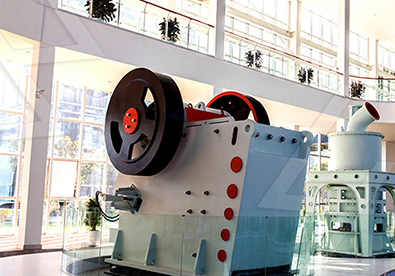

A White Quartz VSI Crusher Sand Making Machine is a specialized type of vertical shaft impact (VSI) crusher designed to produce high-quality artificial sand (manufactured sand) from white quartz or other hard rocks. It is widely used in construction, glass manufacturing, ceramics, and other industries requiring pure silica sand.

Key Features of a White Quartz VSI Crusher Sand Making Machine:

Key Features of a White Quartz VSI Crusher Sand Making Machine:

1. High-Quality Sand Production

– Crushes white quartz into fine, well-shaped sand with uniform particle sizes.

– Produces cubical-shaped sand ideal for construction and industrial uses.

2. Low Iron Contamination

– Uses special wear-resistant materials (like tungsten carbide or ceramic liners) to minimize iron contamination, ensuring high-purity white quartz sand.

3. Energy-Efficient Crushing

– Utilizes a rock-on-rock or rock-on-metal crushing mechanism for efficient shaping and minimal wear.

4. Adjustable Gradation Control

– Allows precise control over the output size (e.g., 0-3mm, 0-5mm) by adjusting rotor speed and feed rate.

5. Durable & Low Maintenance

– Equipped with robust bearings and an optimized crushing chamber for long service life.

Applications of White Quartz VSI Crusher Sand:

Applications of White Quartz VSI Crusher Sand:

– Construction: High-grade concrete, mortar, and asphalt production.

– Glass Manufacturing: Ultra-pure silica sand for glassmaking.

– Ceramics & Refractories: High-purity quartz sand for ceramic glazes.

– Foundry & Casting: Used in molds and cores.

– Water Filtration: Clean silica sand for filtration systems.

Top Manufacturers of VSI Crushers for White Quartz:

– Metso Barmac® B Series (Nordberg)

– Sandvik CV Series

– Terex Canica

– Liming Heavy Industry (China)

– SBM (Shibang Industry & Technology Group)

Considerations When Choosing a White Quartz VSI Crusher:

1. Feed Size & Capacity Requirements – Ensure the machine can handle your desired input size and production rate.

2. Wear Parts Material – Opt for tungsten carbide or ceramic liners to reduce iron contamination.

3. Automation & Control System – Advanced models offer PLC-based control for better efficiency.

4. After-Sales Support

Leave a Reply