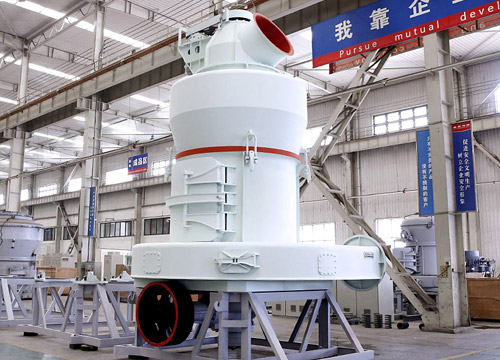

A vertical roller mill (VRM) is a type of industrial equipment used to crush or grind materials into fine powders. It is widely used in cement production, power generation, and mineral processing due to its energy efficiency and ability to handle various materials.

.jpg) Key Components of a Vertical Roller Mill:

Key Components of a Vertical Roller Mill:

1. Grinding Table – Rotates and supports the material bed.

2. Rollers – Apply pressure to the material against the table.

3. Classifier – Separates fine particles from coarse ones for regrinding.

4. Drive System – Powers the rotation of the grinding table.

5. Hydraulic System – Controls roller pressure for optimal grinding.

6. Air System – Facilitates material transport and drying.

Working Principle:

Working Principle:

– Material is fed onto the center of the rotating grinding table.

– Rollers press down on the material, crushing it into fine particles.

– Hot air (in some applications) dries the material while lifting finer particles to a classifier.

– The classifier separates fine product from coarse material, which is returned for further grinding.

Advantages of VRM:

✔ Energy-efficient (lower power consumption than ball mills).

✔ Compact design, requiring less space.

✔ Adjustable grinding pressure & speed for different materials.

✔ Drying capability when integrated with hot gas flow.

✔ Lower noise levels compared to traditional mills.

Common Applications:

– Cement industry (raw meal, clinker, slag).

– Coal/petroleum coke grinding in power plants.

– Ore processing in mining operations.

Would you like details on maintenance, troubleshooting, or specific brands/models? Let me know how I can assist further!

Leave a Reply