Here’s a concise overview of mobile crushing and screening plants, sand screening/breaker plants, and mini crusher plants, along with their key features and applications:

—

1. Mobile Crushing and Screening Plant

– Purpose: Combines crushing and screening in one unit for on-site processing of materials (e.g., aggregates, demolition waste).

– Components:

– Primary Crusher (Jaw/Impact/Hammer).

– Vibrating Screen (for sorting crushed material by size).

– Conveyor Belts (transfer material between stages).

– Advantages:

– Portable (mounted on wheels/tracks).

– Reduces transportation costs.

– Ideal for remote sites or temporary projects.

– Applications: Quarries, recycling, road construction.

—

2. Sand Screening/Breaker Plant

2. Sand Screening/Breaker Plant

– Purpose: Separates sand/gravel by size or breaks down clumps in sand.

– Components:

– Vibrating Screen Deck: Sieves sand into fractions.

– (Optional) Breaker Unit: Crushes oversized lumps.

– Washing System (in wet screening plants).

– Types:

– Dry Screening: For coarse sand/aggregates.

– Wet Screening: Removes silt/clay with water.

– Applications: Concrete production, landscaping, foundry sand preparation.

—

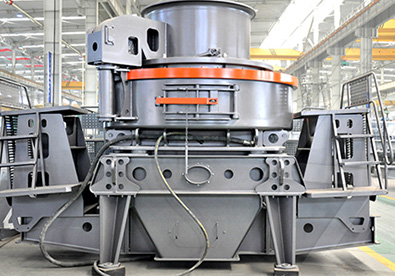

3. Mini Crusher Plant

– Purpose: Compact crusher for small-scale operations or tight spaces.

– Features:

– Small footprint (often trailer-mounted).

– Low power consumption.

– Handles materials like brick, concrete, soft rock.

– Common Types:

– Mini jaw crushers (e.g., PE 150×250 – Hammer mills for brittle materials.

– Hammer mills for brittle materials.

– Applications: Small construction projects, DIY recycling, farm use.

—

Key Considerations When Choosing a Plant

1. Material Type: Hard rock vs. soft/sandy materials.

2. Mobility Needs: Tracked (rough terrain) vs. wheeled (flat sites).

3. Output Capacity: Ranges from <10 tph (mini plants) to 200+ tph (large mobile units).

4. Automation Level: Some models offer remote monitoring.

—

Popular Manufacturers

– Mobile Plants: Metso Lokotrack, Sandvik Mobile Crushers, Kleemann

Leave a Reply