A powder machine crushing equipment is a type of industrial machinery designed to grind, crush, or pulverize solid materials into fine powders. These machines are widely used in industries such as pharmaceuticals, food processing, chemicals, mining, and construction.

Types of Powder Crushing Equipment:

1. Hammer Mill

– Uses rotating hammers to crush materials into powder.

– Suitable for brittle and fibrous materials.

2. Ball Mill

– Uses rotating cylinders with grinding media (balls) to crush materials.

– Common in mining and ceramics industries.

3. Jaw Crusher

– Primary crushing for hard materials (rocks, minerals).

– Produces coarse powder before further refinement.

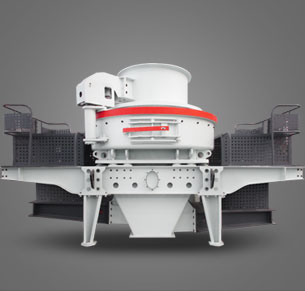

4. Impact Crusher

– High-speed impact breaks materials into fine particles.

– Used in aggregates and recycling industries.

5. Roller Mill

– Uses compression between rollers to crush materials into powder.

– Common in grain processing and cement production.

6. Pulverizer (Grinding Mill)

– Fine grinding for soft to medium-hard materials (coal, spices).

– Used in food and chemical industries.

7. Pin Mill / Air Classifier Mill

– Ultra-fine grinding using high-speed impact and air classification.

– Ideal for pharmaceuticals and cosmetics.

8. Cryogenic Grinder

– Uses liquid nitrogen to freeze and pulverize heat-sensitive materials (plastics, rubber).

.jpg) Key Applications:

Key Applications:

– Pharmaceuticals (tablet production)

– Food processing (spices, sugar, flour)

– Chemicals (pigments, fertilizers)

– Mining & Minerals (limestone, gypsum)

– Recycling (plastic, rubber)

Factors to Consider When Choosing:

Factors to Consider When Choosing:

– Material Hardness: Soft vs. hard materials require different crushers.

– Desired Particle Size: Fine vs. coarse powder needs different milling techniques.

– Moisture Content: Wet vs dry grinding methods vary by machine type.

– Production Capacity: Batch vs continuous processing options available.

Would you like recommendations based on a specific material or industry?

Leave a Reply