Vertical cement mills (also known as vertical roller mills or VRMs) offer several advantages over traditional ball mills in cement grinding. Here are the key benefits:

1. Higher Grinding Efficiency

– Vertical mills use a roller and table system to crush and grind materials, which is more energy-efficient than ball mills (which rely on steel balls tumbling in a drum).

– Lower power consumption (typically 30-50% less than ball mills) due to efficient grinding mechanics.

2. Better Particle Size Distribution & Fineness Control

– VRMs provide a more uniform particle size distribution, improving cement quality.

– Adjustable grinding pressure and speed allow precise control over fineness (Blaine value).

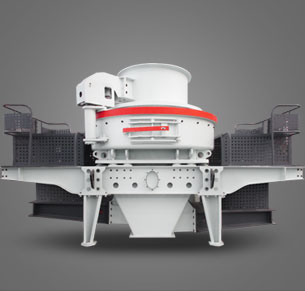

3. Compact Design & Space Savings

– Vertical mills have a smaller footprint compared to ball mills, reducing plant space requirements.

– They can be installed indoors or outdoors, offering flexibility in plant layout.

4. Lower Maintenance & Longer Lifespan

– Fewer moving parts than ball mills, leading to reduced wear and maintenance costs.

– Rollers and tables can be refurbished or replaced individually, minimizing downtime.

5. Drying Capability for Raw Materials

– VRMs can handle moist feed materials (up to 15-20% moisture) without needing a separate dryer, making them ideal for blended cements and slag grinding.

.jpg) 6. Reduced Noise & Vibration

6. Reduced Noise & Vibration

– Vertical mills operate more quietly than ball mills, improving the working environment.

7. Faster Start-Up & Shutdown Times

– Unlike ball mills, which require gradual cooling/heating to avoid thermal stress, VRMs can start and stop quickly.

8. Lower Operating Costs

8. Lower Operating Costs

– Due to reduced power consumption, lower maintenance, and longer service intervals, vertical mills offer significant cost savings over time.

9. Environmentally Friendly Operation

– Lower energy consumption reduces CO₂ emissions per ton of cement produced.

– Some VRMs can incorporate waste heat recovery systems for further efficiency gains.

10. Flexibility in Grinding Different Materials

– Suitable for clinker, slag, fly ash, pozzolan, limestone, and other additives used in modern cement blends.

Conclusion:

Vertical cement mills are increasingly preferred in modern cement plants due to their energy efficiency, operational flexibility, and cost-effectiveness compared to traditional ball mills

Leave a Reply