Here’s an overview of a coal crushing production line in Mongolia, including key components, processes, and considerations:

—

1. Overview of Mongolia’s Coal Industry

– Mongolia is rich in coal resources, with major deposits like Tavan Tolgoi (coking coal) and Baganuur (thermal coal).

– Coal is a critical export commodity (especially to China) and a domestic energy source.

– Crushing is essential for preparing coal for transport, washing, or direct combustion.

—

2. Coal Crushing Production Line Components

A typical production line includes:

# (1) Feeding System

# (1) Feeding System

– Vibrating Feeder: Ensures uniform coal supply to the crusher.

– Hopper: Stores raw coal before processing.

# (2) Primary Crushing

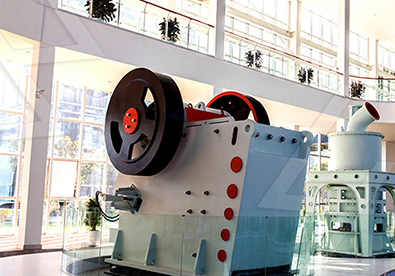

– Jaw Crusher or Rotary Breaker: Breaks large coal lumps (≤1.5m) into smaller pieces (≤200mm).

– *Mongolia’s harsh climate* may require rugged, cold-resistant equipment.

# (3) Secondary Crushing

– Impact Crusher or Hammer Crusher: Further reduces coal to ≤50mm for washing or direct sale.

– Roll Crusher: Used for softer coals to minimize fines.

# (4) Screening

– Vibrating Screen: Separates crushed coal into sizes (e.g., 0-10mm, 10-30mm, 30-50mm).

– Oversized material is recycled to the crusher.

# (5) Conveying System

– Belt Conveyors: Transport coal b een stages (dust-proof designs recommended for dry regions).

een stages (dust-proof designs recommended for dry regions).

# (6) Dust Control

– Dust Suppression Systems (water sprays, bag filters): Critical in Mongolia’s arid climate to meet environmental standards.

—

3. Key Considerations for Mongolia

# (1) Climate Adaptations

– Extreme temperatures (−40°C winter, +40°C summer): Equipment must be winterized (heated lubricants, insulated enclosures).

– Dust storms: Enclosed conveyors and shelters may be needed.

# (2) Logistics & Infrastructure

– Remote mining sites: Mobile or modular crushing plants can reduce transport costs.

– Export-focused lines: Crushed coal often loaded directly onto trucks/trains bound for China.

# (3) Environmental Compliance

– Mongolia enforces air quality laws (e.g., dust emissions). Wet crushing or enclosed