Refractory crushing involves processing materials that are highly resistant to heat and wear, such as firebricks, ceramics, and other high-temperature-resistant aggregates. Specialized equipment is required to handle these tough materials efficiently. Below are key types of refractory crushing aggregate equipment and considerations:

1. Primary Crushing Equipment

– Jaw Crushers: Robust for coarse crushing of refractory materials (e.g., alumina, magnesia bricks).

– Example: Heavy-duty jaw crushers with manganese steel liners.

– Gyratory Crushers: Suitable for large-scale refractory processing with high capacity.

2. Secondary Crushing Equipment

– Cone Crushers: Ideal for medium-hard to hard refractory materials (e.g., silica, zirconia).

– Hydraulic adjustment for precise output sizing.

– Impact Crushers (Horizontal/Vertical Shaft): Effective for brittle refractories (e.g., chamotte, fused cast blocks).

– Uses hammers/blow bars for impact crushing.

3. Tertiary/Fine Crushing Equipment

3. Tertiary/Fine Crushing Equipment

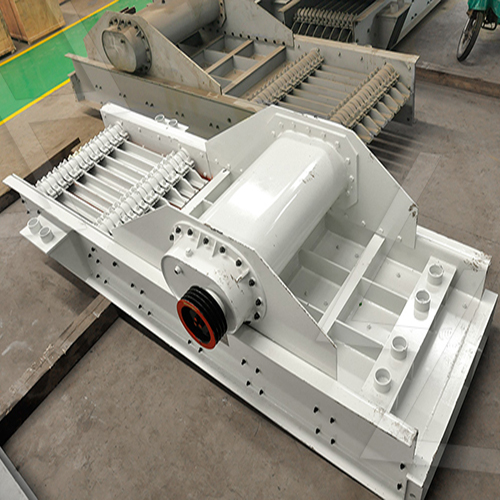

– Roll Crushers: For fine grinding of refractory aggregates (e.g., grog, dead-burned magnesite).

– Adjustable gap settings for controlled particle size.

– Hammer Mills: Efficient for pulverizing refractory waste into fine powders.

4. Specialized Refractory Processing Equipment

– Ball Mills/Rod Mills: Used in refractory recycling or fine grinding applications.

– VSI Crushers (Vertical Shaft Impactors): Produces cubical-shaped aggregates for refractory mixes.

5. Auxiliary Equipment

– Vibrating Screens: Classify crushed refractory materials by size.

– Magnetic Separators: Remove metallic contaminants from recycled refractories.

– Dust Collection Systems: Essential due to silica/alumina dust hazards.

Key Considerations When Selecting Equipment

– Material Hardness & Abrasiveness → Choose wear-resistant alloys (e.g., tungsten carbide, high-chrome steel).

– Moisture Content → Jaw/cone crushers handle dry materials better; impact crushers may struggle with sticky refractories.

– Output Size Requirements → Adjustable crusher settings for custom gradations.

– Durability & Maintenance → Re ctory crushing is abrasive; prioritize easy-to-replace wear parts.

ctory crushing is abrasive; prioritize easy-to-replace wear parts.

Leading Manufacturers