The Ground Calcium Carbonate (GCC) process involves extracting, crushing, grinding, and classifying limestone or marble to produce fine or ultra-fine calcium carbonate powder. Here’s a step-by-step breakdown of the typical GCC production process:

1. Mining & Quarrying

– Limestone or marble is extracted from open-pit mines or quarries using drilling and blasting techniques.

– High-purity deposits (≥95% CaCO₃) are preferred for high-quality GCC.

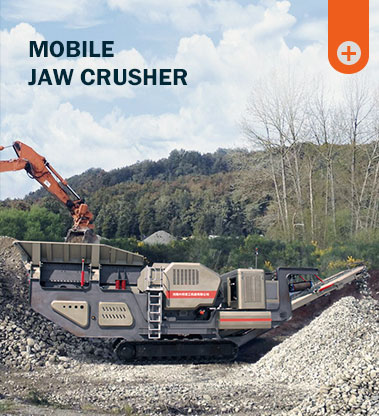

2. Primary Crushing

– Large rocks are crushed into smaller pieces (typically <50 mm) using jaw crushers, impact crushers, or hammer crushers.

3. Washing & Beneficiation (Optional)

– Impurities like clay, silica, and iron are removed through:

– Wet scrubbing (for clay removal).

– Magnetic separation (for iron removal).

– Froth flotation (if high purity is required).

4. Grinding (Dry or Wet Process)

# (a) Dry Grinding Process

– Crushed limestone is dried and fed into a ball mill, vertical roller mill, or pendulum mill.

– Ground material is classified by an air classifier to separate fine particles (<10–45 µm).

– Coarse particles are recycled for further grinding.

# (b) Wet Grinding Process

# (b) Wet Grinding Process

– Used for ultra-fine GCC (<2 µm).

– Limestone is ground in a wet ball mill or attrition mill with water.

– A hydrocyclone or centrifuge separates fine slurry from coarse particles.

.jpg) 5. Classification & Separation

5. Classification & Separation

– Air classifiers (dynamic or static) separate particles by size in dry processes.

– Hydrocyclones or centrifuges classify wet-ground slurry.

6. Surface Treatment (Optional)

– For specialty applications, GCC may be coated with:

– Stearic acid (for hydrophobic properties in plastics).

– Titanate/silane coupling agents (for improved polymer compatibility).

7. Drying (Wet Process Only)

– Filtered slurry is dried in a spray dryer, rotary dryer, or flash dryer to remove moisture.

8. Packaging & Storage

– Final GCC powder is packed in bags, bulk containers, or silos based on customer requirements.