The installation of stone crushing equipment involves several key steps to ensure proper setup, safety, and operational efficiency. Below is a step-by-step guide:

—

1. Site Preparation

– Land Clearing: Remove vegetation, debris, and obstacles from the site.

– Leveling: Ensure the ground is level and stable for equipment placement.

– Foundation Construction:

– For stationary plants: Pour a concrete foundation with anchor bolts for stability.

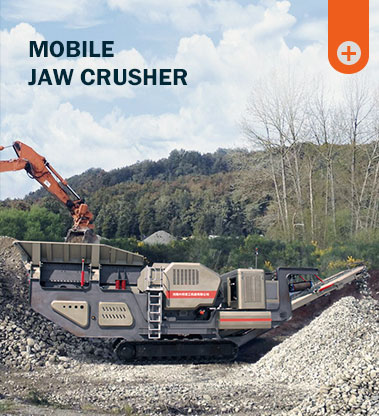

– For mobile crushers: Compact the ground to prevent sinking or shifting.

2. Equipment Delivery & Inspection

2. Equipment Delivery & Inspection

– Transport crushers, screens, conveyors, and auxiliary equipment to the site.

– Inspect all components for damage or missing parts before installation.

3. Assembly of Major Components

– Primary Crusher (Jaw/Cone/Impact Crusher):

– Position on the foundation or chassis.

– Secure with bolts or welding (for stationary units).

– Secondary/Tertiary Crushers: Install downstream units as per the crushing circuit design.

– Vibrating Screens: Mount on a stable base with vibration isolation pads.jpg) Conveyors & Feeders: Align belts and adjust tension to prevent slippage.

Conveyors & Feeders: Align belts and adjust tension to prevent slippage.

4. Electrical & Control Systems

– Connect motors, control panels, and sensors to the power supply.

– Install safety switches, emergency stops, and overload protection.

– Test automation systems (if applicable).

5. Dust Suppression & Water Spray Systems

– Install nozzles near crushing/screening points to minimize dust.

– Connect water supply lines and pumps.

6. Final Checks & Commissioning

– Lubricate bearings, gears, and moving parts.

– Tighten all bolts and fasteners.

– Run a no-load test to check vibrations, alignment, and unusual noises.

– Gradually feed material for a full operational test.

—

Key Safety Considerations

✔ Wear PPE (helmets, gloves, ear protection).

✔ Follow manufacturer’s guidelines for installation tolerances.

✔ Ensure proper guarding around moving parts (belts, rotors).

✔ Comply with local environmental regulations (noise/dust control).

—

Maintenance Tips After Installation

– Regularly inspect wear parts (liners, hammers, screens).

– Monitor belt tension and alignment.

– Keep crusher cavities clear of blockages.

For complex setups (e.g., large-scale quarry plants), consult professional engineers or the equipment supplier for detailed installation support.