The iron ore manufacturing process involves several stages to convert raw iron ore into usable iron or steel products. Here’s a step-by-step breakdown:

1. Mining

– Iron ore is extracted from open-pit or underground mines.

– Common types of iron ore include hematite (Fe₂O₃) and magnetite (Fe₃O₄), with varying iron content (30–70%).

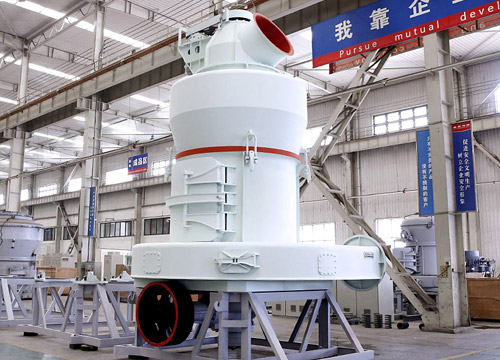

2. Crushing & Screening

– Mined ore is crushed into smaller pieces (lumps/fines) and screened to remove impurities.

– Low-grade ores may undergo beneficiation (enrichment) to increase iron content.

3. Beneficiation (Optional)

3. Beneficiation (Optional)

– Techniques like gravity separation, magnetic separation, or flotation remove gangue (waste material).

– The result is a higher-grade iron ore concentrate (~60–65% Fe).

4. Agglomeration (Pelletizing/Sintering)

– Fine ore is processed into pellets or sinter for efficient blast furnace use:

– Pelletizing: Ore fines are rolled into small balls and hardened by firing.

– Sintering: Fine ore is mixed with coke breeze and heated to form a porous mass.

5. Ironmaking (Blast Furnace or Direct Reduction)

# (a) Blast Furnace Route (Traditional Method)

– Iron ore, coke (carbon source), and limestone (flux) are fed into a blast furnace.

– Hot air (~1200°C) is blasted in, reducing iron oxide to molten pig iron (~4% carbon).

– Impurities form slag, which is removed.

# (b) Direct Reduced Iron (DRI / Sponge Iron)

– Uses natural gas or coal to reduce iron ore pellets/lumps in a shaft furnace (MIDREX, HYL process).

– Produces solid spong ron (~90–94% Fe), later melted in an electric arc furnace.

ron (~90–94% Fe), later melted in an electric arc furnace.

6. Steelmaking

Pig iron or DRI is refined into steel:

# (a) Basic Oxygen Furnace (BOF)

– Pig iron + scrap steel + oxygen → removes excess carbon & impurities.

# (b) Electric Arc Furnace (EAF)

– Scrap steel or DRI melted using electric arcs; common for recycling.

7. Casting & Rolling

– Molten steel is cast into slabs, bille