Waste red bricks were originally used to build buildings, such as roads in cities and walls beside roads, but over time, their lifespan gradually decreased and they became dilapidated.In order to avoid throwing them away and wasting them, let’s talk about whether the waste red bricks can be broken and reused.What equipment is used for crushing waste red bricks?

Can the waste red bricks be broken and reused?

is ok, some customers will worry that the hardness of the waste red brick itself is not high, and there is no commercial use after crushing. After all, in the current construction engineering market, the requirements for sand and gravel aggregates are so high that waste red bricks are difficult to achieve. If you work hard to build a waste red brick treatment plant, but it can’t bring users the benefits they deserve, that’s a very annoying thing. thing.In fact, the hardness of waste red bricks is not high, but it is not a non-high-quality sand and gravel aggregate in the field of construction projects.Like some non-load-bearing block bricks, as well as permeable bricks, roadside bricks, water-stabilized base materials, subgrade and other places that do not require high sand and gravel aggregates, the recycled sand and gravel crushed with waste red bricks can not only meet the building requirements, but also save energy and reduce consumption and save expenses.Of course, since red bricks may contain heavy metals, it is necessary to pay attention to the emission standards of heavy metals when using them.

What equipment is used for crushing waste red bricks?

Waste red brick crusher equipment is a kind of waste recycling machinery. It mainly breaks large pieces of red bricks into sand and gravel aggregates for reuse. There are mainly two types of fixed and mobile all-in-one machines. The equipment models are complete and can be reasonably selected according to actual production capacity, discharge, site conditions and investment budget. Let’s take a look in detail below.

Jaw crusher: Feed particle size≤1200mm, processing capacity 1-1000t/h.

The jaw crusher has no dead zone for deep cavity crushing, and can completely crush waste red bricks.The mobile fixed jaw plate is made of high-quality alloy materials, with strong wear resistance, large crushing rate, large one-time processing capacity, reasonable structural design, stable operation, good energy-saving and environmental protection effects, less dust overflow in the production process, and low working noise.

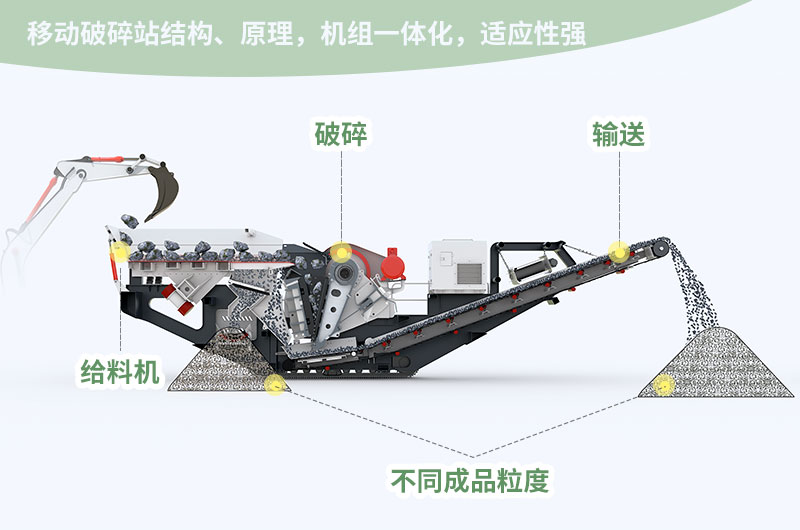

Mobile crusher: Feed particle size≤800mm, processing capacity 85-650t/h.

A mobile crusher can be used as a complete production line, which can be realized through feeding, transportation, crushing and screening.It is divided into crawler and mobile, and can freely enter and exit the work site.The stretching equipment can work directly without a cement foundation.This kind of dual-purpose oil-electric power plant can ensure the smooth progress of production, intelligent operating system, and save manpower and material resources.

After the waste red bricks are broken, they only need to be reused to greatly reduce pollution, and at the same time they can save time and energy. Why not.If you are interested in our products or have any questions, please click“ business Through ” For consultation, our customer service staff will provide you with detailed answers and thoughtful service. Your satisfaction will be our unremitting driving force for progress. You are welcome to click for consultation.

Leave a Reply