Sand and gravel are indispensable main raw materials in construction, infrastructure, and transportation construction. With the acceleration of the pace of national infrastructure construction, the amount of sand and gravel has increased sharply. China’s demand for sand and gravel currently exceeds 10 billion tons, and the industrial scale is more than 500 billion yuan.However, the increasing shortage of river sand resources has caused insufficient supply, rising prices, and large fluctuations in quality. Traditional mechanism sand is rough and angular, uneven gradation, excessive impurities, and insufficient performance. This is undoubtedly worse for the construction industry where sand and gravel resources are scarce.After years of special research, Liming Heavy Industry has overcome the multiple problems of breaking, grinding, and selection in the optimization process, and launched the VU aggregate optimization system. So, what about the VU aggregate optimization system of Liming Heavy Industry?Next, Xiaobian will explain one by one.

Details of the VU aggregate optimization system

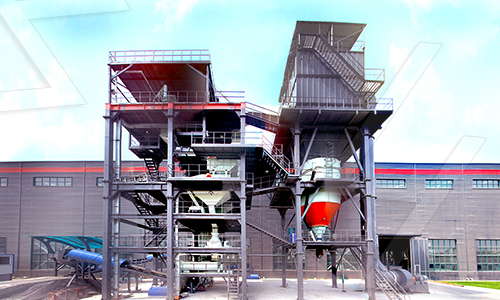

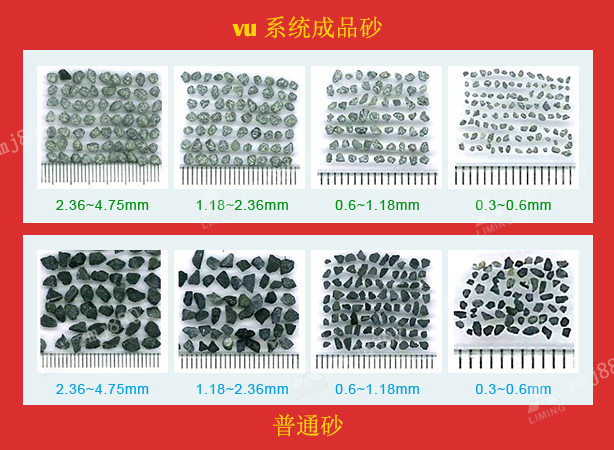

The VU aggregate optimization system is based on the design concept of “high-quality, intensive, green and environmentally friendly”, and is a tower-type fully enclosed system integrating sand screening, particle size optimization, stone powder control, grading adjustment, moisture content control, and environmental protection treatment.The dry sand process is used to solve the production problem of high-quality mechanism sand, thereby creating new opportunities and value for the development of the sand, cement and concrete industry chain.The system reproduces the effects of natural crushing, erosion and friction, and natural washing and selection in the process of natural sand and gravel formation as much as possible.Raw materials of 0-25mm, even cheap and easy-to-obtain raw materials such as stone chips and guami stone, can be processed by the VU system to produce finished sand with reasonable grade, round grain shape and controllable powder content, as well as dry and clean, high-value-added stone powder that can be uniformly recycled (the scope of application is determined according to the raw materials).

Technical advantages of VU aggregate optimization system

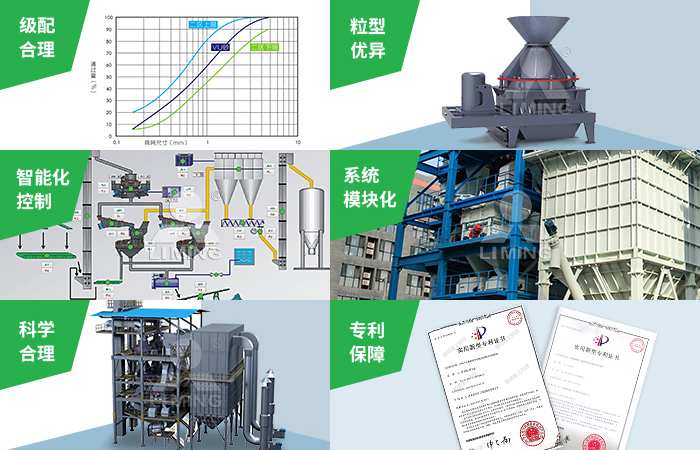

1. level cooperation management. The comprehensive breaking and grinding effect and flexible screening design have made the grade of finished sand continuous and adjustable, and the proportion of 0.15-0.6mm fine sand has been greatly increased, and the proportion of 2.36-4.75mm coarse sand has decreased, which meets the limitations of industry standards such as ASTM C33 in the United States, JGJ52 Zone 2 in China and IS383 Zone 2 in India.

2. Excellent particle size. The use of self-created grinding technology and waterfall shaping technology, so that the finished sand grain type is mainly high square and spherical, the surface edges and burrs are greatly reduced, the surface area and porosity are significantly reduced, and the fluidity is improved.

3. intelligent control. Supporting a central control system, one-click start/stop, real-time monitoring of the operating status of each host, to ensure that the system runs 24 hours a day, continuous and stable production.

4. The system is modular. The highly intensive tower-style fully enclosed layout, and the steel structure is all bolted to achieve modular and rapid installation.

5. Scientific and reasonable. The production process is scientific and reasonable: the raw materials are lifted and transported to the top for crushing, screening, grinding, humidification, and discharging. Under the action of gravity, they fall smoothly, reducing the use of belt conveyors, reducing system openings, improving dust removal effect, and reducing system noise.

6. Patent protection. The core hosts are all independently developed and produced, with a number of national patented technologies (patent number: ZL 201721668562.9 ZL 201721668856.1), high compatibility and good adaptability of each equipment

High degree of automation, easy operation, integrated modularity, compact equipment, scientific process flow, smooth production, complete product spectrum, wide coverage

Technical parameters of VU aggregate optimization system

| Model number | Feeding particle size (mm) | Raw material input (t/h) | Stone powder content (adjustable) | Installed power (kW) | Dimensions (mm) |

|---|---|---|---|---|---|

| VU100 | 0-25 | 80-100 | 3-15% | ~680 | 19000×10500×22400 |

| VU150 | 0-25 | 125-150 | 3-15% | ~995 | 21900×11300×22900 |

| VU300 | 0-25 | 240-300 | 3-15% | ~1990 | 25000×15200×22900 |

The above is the explanation of Liming Heavy Industry’s VU aggregate optimization system. If you are interested in our products or have any questions, please feel free to call us whatsapp:+8613633818807 or click“Business Pass” For consultation, our customer service staff will provide you with detailed answers and thoughtful service. Your satisfaction will be our unremitting driving force for progress. You are welcome to click for consultation.

VU aggregate optimization System headquarters Address: No.169, Science Avenue, High-tech Industrial Development Zone, Zhengzhou, China