Copper mines are complex in nature, and the mineral structure is also complex and diverse. After entering the 21st century, copper is widely used and used in the electrical and electronics industries. It is mainly used in the manufacture of various electronic products such as mobile phones and computers, accounting for more than half of the total consumption.As one of the core materials needed in the high-tech industry, it has extremely high economic value.So, how can the mined copper ore be turned into copper of high economic value?What equipment is needed in the processing of copper ore, and what is the role of these main equipment?Let’s reveal it together.

Copper ore crushing process flow

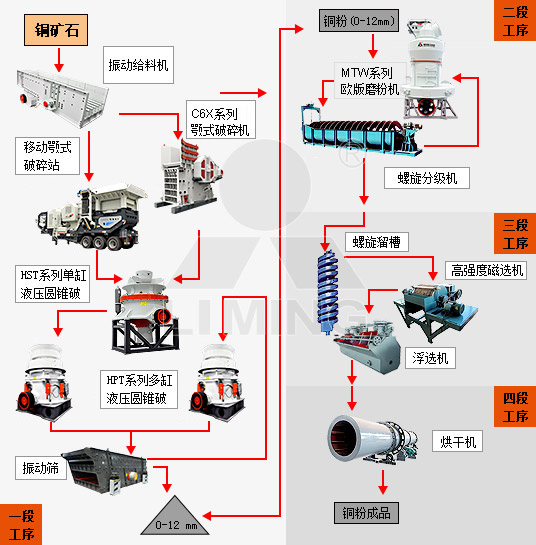

The processing technology of copper ore mainly includes: crushing, grinding, and mineral processing three processes.In the crushing process, modern high-hardness crushing technology is mainly used for three-stage closed-circuit crushing; this stage can mainly complete the crushing and decomposition of copper ore to improve the efficiency of the subsequent grinding stage; in the grinding process, the two-stage and one-closed grinding is an efficient grinding process, which can make the copper ore milled more fully; in the mineral processing process, the more successful new processes that have emerged in recent years are mainly representative of the mixed flotation process.

The first stage: crushing and screening-three-stage closed-circuit crushing. Large pieces of copper ore are evenly fed into the jaw crusher or coarse crushing mobile station (initial breaking) by the vibrating feeder through the silo for coarse crushing; after the coarse crushing copper ore is sieved by the vibrating screen, it is sent by the belt conveyor to the single-cylinder hydraulic cone crusher (second breaking) for medium crushing; the copper ore material after medium crushing is fed into the multi-cylinder hydraulic cone crusher for fine crushing;

The second stage: grinding-two stages and one closed grinding. The 0-12mm copper powder sieved by the vibrating screen is evenly fed into the mill for grinding, and it is sieved by the spiral classifier, and those that do not meet the requirements are fed into the mill to continue grinding;

The third stage: mineral processing-a new process for flotation and sorting. The copper powder that meets the requirements is fed into the flotation machine for mixed flotation, and then the obtained copper powder is fed into the dryer for drying to obtain copper fine r fine powder.

Flow chart of copper ore crushing process

the site of the copper ore crushing and processing production line

Kenya copper ore processing production line

Application area: Metal smeltingProcessing materials: copper ore Production: 5000 tons/dayEquipment configuration: HPT hydraulic cone crusher, jaw crusher, etc.

Customer feedback: Purchased a complete copper ore dressing production line, which integrates crushing, grinding, flotation, drying and packaging.Since this production line was put into operation last year, there have been basically no problems, the quality is guaranteed, and it has created very rich profits for customers.After gaining the trust of our customers, our products have been recommended to dozens of local metal smelters, large and small, and now they have basically covered the copper smelting market in Jiangmen.

Zimbabwe copper ore mining production line

Application field: Metal smeltingProcessing materials: copper ore Production: 8000 tons/dayEquipment configuration: HST single-cylinder hydraulic cone breaking, jaw breaking, etc.

Customer feedback: The effect of using Liming crusher to process copper ore for metal smelting is really good.In addition to solid product quality, more importantly, the environmentally friendly design is superior.For companies with relatively serious pollution like our heavy metal processing plants, being able to reduce waste emissions during the mineral processing stage is an important guarantee for us to maintain production.There is also an annual technical maintenance. Liming Heavy Industry engineers will conduct detailed inspections of the equipment, and they have taught us a lot of maintenance knowledge, which has benefited a lot.

copper ore crushing and processing factory services

Liming Heavy Industry has always stood from the perspective of customers and established a complete set of service policies for customers. The company is in line with a serious attitude of being responsible for every customer, from pre-sales guidance, investment prospect analysis, equipment visits, on-site surveys, signing contracts during sales, testing machines, to free on-site installation, repair, maintenance and a series of technical guidance, to the company’s regular return visits during the customer’s production process, etc., have brought us closer to our customers; in addition, there is our national online one-to-one service online consultation , 365×24 hours online, always waiting for your consultation and feedback, we will solve any problems you encounter in the first time!

Copper ore crushing and processing production line headquarters address: No.169, Science Avenue, High-tech Industrial Development Zone, Zhengzhou, China