The river pebble crushing production line uses a series of machinery and equipment to break large pieces of river pebbles into gravel of different specifications to meet the needs of construction projects, road construction and other industries.So how to configure the river pebble crushing production line?What are the plans?Today we will talk about it in detail.

How to configure the river pebble crushing production line?

As a kind of pure natural stone, river pebbles have the characteristics of compression resistance, wear resistance, and strong corrosion resistance. They are widely distributed, rich in resources, low collection cost, and high application value. The comprehensive hardness is above 7 degrees Mohs, and the compressive strength is as high as 300MPa or more.Natural river egg ore is crushed and processed to produce river egg sand, which is an important industrial mineral raw material, and the processing process requires the use of vibrating feeders, jaw crushers, impact crushers, cone crushers, sand making machines, vibrating screens, sand washing machines, belt conveyors and other equipment.

Feeder: The role of the feeder is to evenly feed the raw ore into the jaw crusher for initial crushing, and the crushed ore continues to enter the impact crusher for multi-stage crushing.

Jaw crusher: The jaw crusher is the primary crushing equipment in the river pebble crushing production line. It uses the principle of oblique collision between the moving jaw and the static jaw to crush large pieces of river pebble material into small pieces.

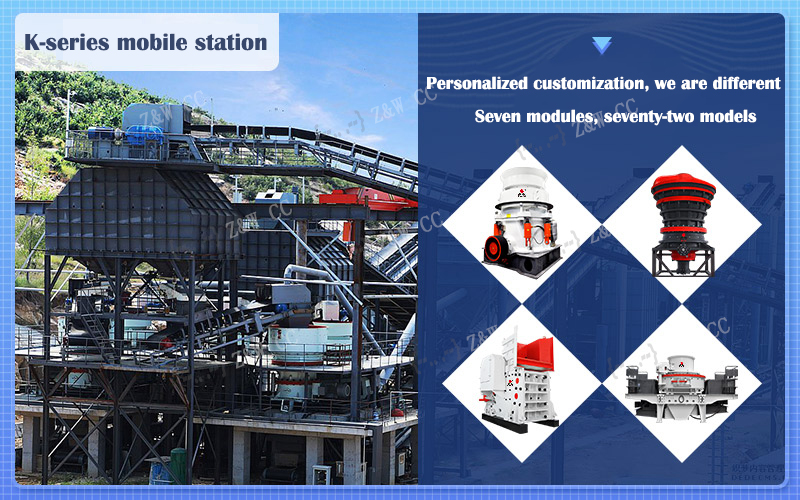

Impact crusher/cone crusher: Impact crusher/cone crusher uses impact energy to finely crush medium-hardness brittle materials, and the river pebble material processed by the first-stage jaw crusher enters the impact crusher/cone crusher for secondary crushing, and the material is processed to the required fineness.

Belt conveyor: A belt conveyor is a transmission equipment for ore materials, which transmits the ore materials after secondary crushing to a vibrating screen for screening.

Vibrating screen: The role of vibrating screen is to screen the ore materials processed by the impact crusher, enter the next process of the materials that meet the requirements, and return the materials that do not meet the requirements to the impact crusher for re-crushing.

Configuration plan of river pebble crushing production line

- The secondary crushing method of jaw crusher and impact crusher has less initial investment, and the accessories of the impact crusher are relatively worn out, which is suitable for customers with relatively small output and not very well-funded funds.

The configuration is: stone-silo-feeder—jaw crusher-belt conveyor—impact crusher—belt conveyor—vibrating screen (primary screening, and impact crusher to form a closed circuit cycle)—vibrating screen (grading and screening of finished materials)—belt conveyor-finished materials.

- The secondary crushing process of jaw crusher and single-cylinder hydraulic cone crusher has large initial investment, high degree of intelligence, easy adjustment, low maintenance rate, and low maintenance costs in the later stage. It is the main choice for large-scale hard rock (river pebbles, granite, basalt, etc.) crushing production lines.

The configuration is: stone-silo—feeder—jaw crusher-belt conveyor—single—cylinder hydraulic cone crusher—belt conveyor—vibrating screen (primary screening, and single—cylinder cone crusher closed circuit cycle)-vibrating screen (grading and screening of finished materials)-belt conveyor-finished materials.

The above is the configuration of the river pebble crushing production line.