Basalt, a kind of high-quality stone widely used in construction, road laying and other fields, the selection and configuration of crushing equipment is of great significance to improve production efficiency and reduce costs.This article will introduce in detail the main types of basalt crushing equipment with a hourly output of 50 tons and their prices to help you better choose the equipment that suits you.

What are the equipment for crushing basalt with a hourly output of 50 tons?

- Jaw crusher: Jaw crusher is the preferred equipment for basalt crushing, suitable for coarse and medium crushing links.It has the advantages of simple structure, large crushing ratio, low noise, and easy maintenance.

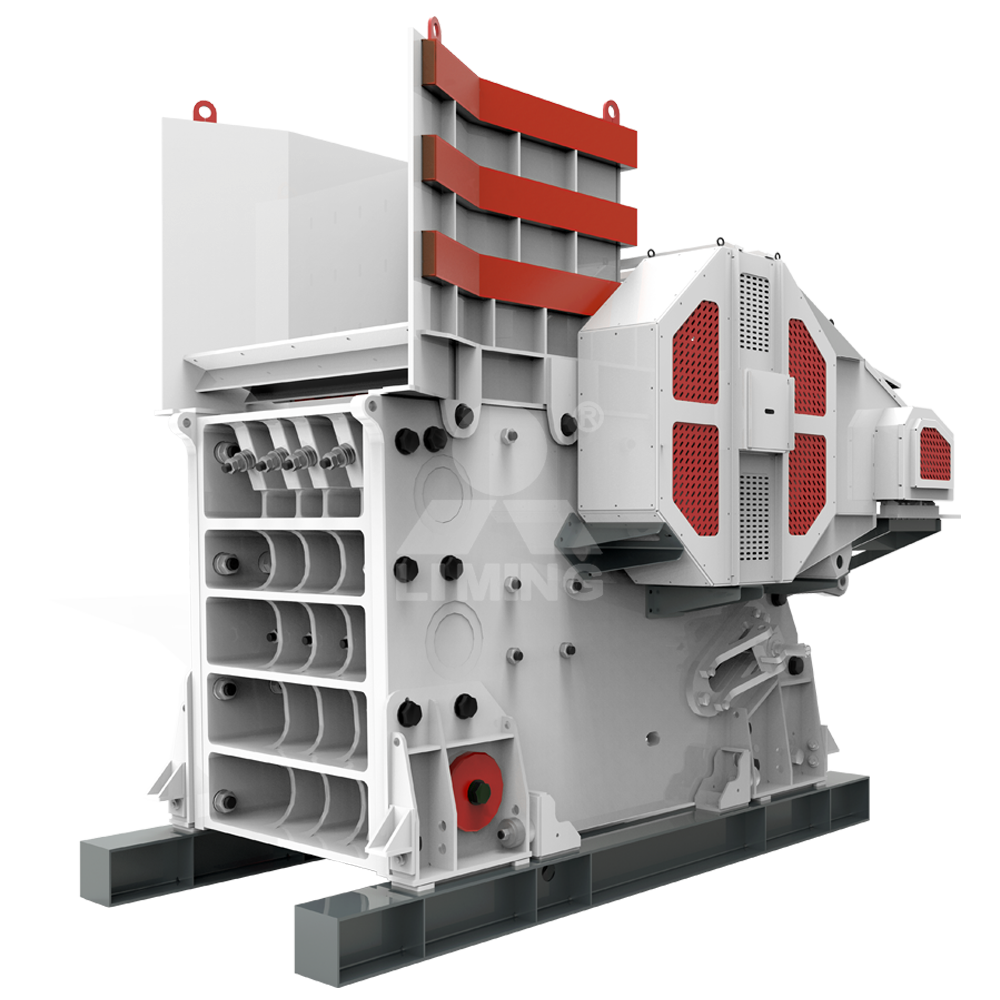

- Impact crusher: Impact crusher is one of the commonly used equipment in the field of basalt crushing.Its working principle is to use the collision and friction between the counterattack plate on the high-speed rotating rotor and the material to break the material.The impact crusher has the characteristics of high crushing efficiency, large crushing ratio, uniform product particle size, etc., and is suitable for crushing medium hardness and brittle materials.

- Cone crusher: Cone crusher is also one of the commonly used equipment in the field of basalt crushing.Its working principle is that through the relative rotation between the moving cone and the fixed cone, the material is subjected to various crushing effects such as extrusion, bending and shear in the crushing chamber, so as to achieve crushing.The cone crusher has the characteristics of high crushing efficiency, large processing capacity and stable operation, and is suitable for crushing high-hardness materials.

- Impact crusher: Impact crusher is suitable for fine crushing and ultra-fine crushing links, with high crushing speed and crushing effect.It is suitable for crushing materials with high hardness, high humidity and high wear.

How much is the hourly production of 50 tons of basalt crushing equipment?

- Equipment models and specifications: The prices of different models and specifications of equipment will vary.Generally speaking, the higher the output, the larger the equipment specifications, and the higher the price.

- Equipment quality: The quality of equipment directly affects the production efficiency and crushing effect, and the price of high-quality equipment is relatively high.

- Brand influence: Equipment of well-known brands usually has high quality assurance and after-sales service, so the price is relatively high.

- Market demand and supply: Market demand and supply will also have an impact on equipment prices.In the case of high market demand and tight supply, equipment prices may rise.

All kinds of equipment have different characteristics and scope of application, and users can choose suitable equipment according to their actual needs.