Regarding the types of concrete crushers, there are three main types: coarse crushing and medium-fine crushing. Among them, coarse crushing equipment refers to jaw crushers, medium-fine crushing equipment refers to cone crushers and counterattack crushers. Each of these three types of equipment has many different models. In terms of production capacity, it can also meet the requirements for production capacity in different production, so it better meets the requirements of different production projects for concrete processing, so for a concrete crusher with a hourly output of 100 tons, which one is better?

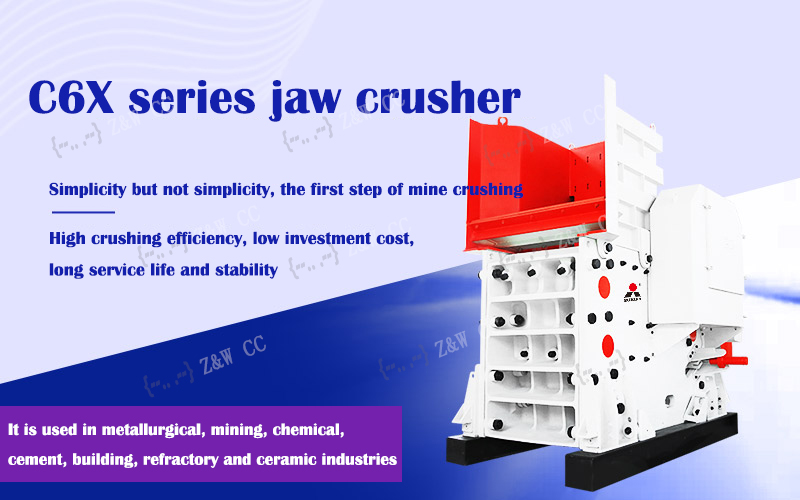

First of all, whether it is a jaw crusher, a counterattack crusher or a cone crusher, the requirements for a production capacity of 100 tons/hour can be met. Among them, there are three common types of jaw crushers: PEW jaw crusher, PE jaw crusher, and C6X jaw crusher. The production capacity is 12-650 tons/hour, 45-800 tons/hour, and 160-1510 tons/hour. Common types of counterattack crushers are CI5X counterattack crusher, PFW counterattack crusher, and PF counterattack crusher. The production capacity of the cone crusher is 250-2000 tons/hour, 70-400 tons/hour, and 50-220 tons/hour. The common types of cone crushers are: HPT multi-cylinder hydraulic cone crusher, HST single-cylinder hydraulic cone crusher, and CS spring cone crusher. The production capacity is 45-1200 tons/hour, 45-2130 tons/hour, and 45-1400 tons/hour. It can be seen that in these three types of concrete crushers, there is always a time to meet the production requirements. 100 tons of required equipment;

Secondly, when crushing concrete, different crushing requirements choose different crushers. For example, for the coarse crushing of concrete, you need to choose jaw breaking, and for medium and fine crushing, you need to choose counter-breaking or cone breaking. The two functions are similar, but the production process and results are very different. For example, the two are very different in terms of the quality of the finished products produced. There are fewer needle-like materials in the finished products that are counter-broken and the quality is better.

For the question of which crusher to choose to process concrete, it mainly depends on the customer’s production requirements. If it is coarse crushing production, jaw breaking is better. For medium and fine crushing, you can choose counterattack breaking or cone breaking. The processing principles and production requirements of the two are different.