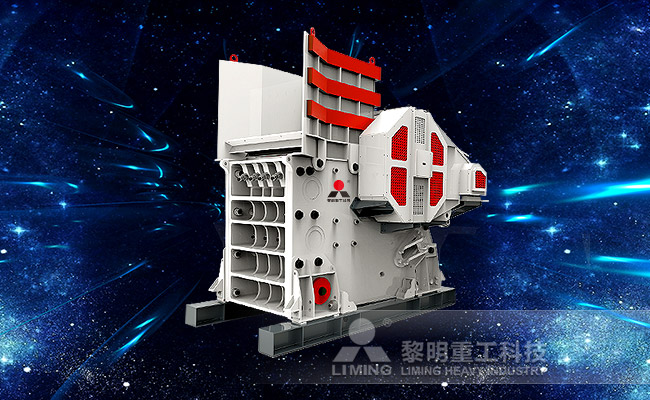

Jaw crusher is a commonly used crushing equipment in coarse crushing operations. It is widely used in the crushing of ore and large materials in mining and smelting, building materials, roads, railways, water conservancy and chemical industries.The phenomenon of rework may occur when the jaw crusher is working: the material is not squeezed by the movable jaw plate and the fixed jaw plate, but is squeezed out of the inlet.This situation will not only reduce production efficiency, but may also cause harm to the human body.This article mainly shares the reasons and solutions for the rework of jaw crushers.

The reason for the return of broken jaw

- The problem of the jaw crusher itself

The parts of the new jaw crusher do not match the dimensions of the drawings, such as the length and thickness of the jaw plate, the length of the elbow plate and the angle of the elbow plate, the size of the inner cavity of the rack, etc. Are not standardized, resulting in inferior products; after long-term use, the angle between the two jaw plates is greater than twice the friction angle, so that the material and the jaw plate can not produce a large enough friction force to overcome the upward force of the crushing force, and the material is squeezed out under the action of vertical upward force and slides in the direction of the inlet. - Material force imbalance

The force of the material to be broken in the vertical direction of the crushing chamber is easily unbalanced, and under the action of upward force, the phenomenon of rework is prone to occur. - The width of the discharge port is too large

For jaw crushers of the same specification, the larger the width of the discharge port, the more likely it is to rework.During the crushing process, the material is in direct contact with the jaw plate, causing friction.The more severe the wear and tear of the jaw plate, the greater the possibility of rework. - The size of the material to be broken is too different

When the size of the material to be broken by the crusher varies greatly, it is easy to rework.

Solution to broken jaw and rework

- According to the material situation, use a crusher of suitable specifications.

- When the jaw plate is worn out and the phenomenon of rework occurs, the new jaw plate should be repaired or replaced in time.

- When the particle size difference of the material is too large, the screening is carried out first; the coarse jaw crusher is pre-processed, and then the fine jaw crusher is used for finishing, which can ensure the processing requirements of the material.

- At the junction of the moving jaw and the movable jaw plate, add a wedge-shaped pad to reduce the angle between the two jaw plates so that it satisfies the friction angle between the two jaw plates that is less than twice the angle, and eliminates the phenomenon of rework.

- The guard plate can be welded above the jaw-breaking inlet to prevent the material from flying out of the inlet and endangering the personal safety of the operator.

Note: After the return of the material occurs, the operator must pay attention to safety!

When the jaw crusher is returned to the material, the maintenance personnel should find out the cause and take corresponding countermeasures to avoid affecting production.Welcome to leave a message to discuss the problems you have encountered.