With the continuous advancement of domestic infrastructure construction projects, the construction and development of various buildings and roads require a large amount of sand and gravel aggregates. The supply of sand and gravel in the current sand and gravel market is obviously insufficient, and the price of sand and gravel has been rising, so more and more customers are beginning to invest in sand and gravel plants.

How much does it cost to invest in a sand and gravel plant with a daily output of 2,000 tons? It depends on the equipment configuration plan of the sand and gravel production line you choose. Generally speaking, for a daily output of 2,000 tons, the quoted price of sand and gravel production line equipment will be around several million. The higher the equipment configuration level and the more complete the auxiliary equipment, the better the production effect.

What equipment does a sand and gravel production line with a daily output of 2,000 tons have? Quotation depends on configuration

The working time of general sand and gravel plant equipment is 8-10 hours, and it needs to achieve a daily sand production output of 2,000 tons, that is, 200-250 tons/hour.

So, what exactly is the equipment for a sand and gravel production line with a daily output of 2,000 tons? What’s its price? Let’s do a detailed analysis and answer below.

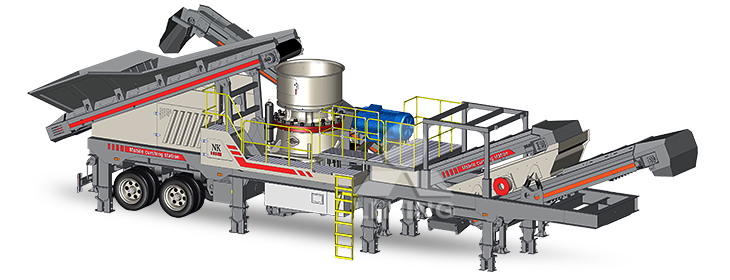

The sand and gravel production line with a daily output of 2,000 tons has various equipment types and many options.

Coarse crushing equipment: C6X80 jaw crusher, PE750×1060 jaw crusher, PEW760 jaw crusher.

Secondary crushing equipment (medium and fine crushing): PF1315 impact crusher, PFW1315Ⅲ impact crusher, HPT200 multi-cylinder hydraulic cone crusher, HST250 single-cylinder hydraulic cone crusher.

Sand making equipment: VSI6X1040 sand making machine, VSI5X9532 impact sand making machine, VSI9526 sand making machine.

Which sand and gravel production equipment is the cheapest to invest in?

Which manufacturer’s sand and gravel production equipment quote is cheaper? It belongs to Shibang Group. The manufacturer adopts a direct sales model without middleman price differences, optimizes the equipment production process, and has mature technology to reduce equipment costs and provide customers with cheaper quotes.

In the golden autumn, Shibang Group has launched a preferential activity. Customers who come to the factory to inspect can enjoy preferential equipment quotations, and professional technical managers will provide you with one-on-one guidance on purchasing machines.