Sand and gravel resources are in short supply, and the output and benefits of the sand and gravel crushing production line have attracted the attention of many investors. A production line with reasonable configuration and advanced technology can bring considerable benefits to customers. So how to configure an efficient sand and gravel crushing production line, what is the process flow?

Sand and gravel crushing production line equipment

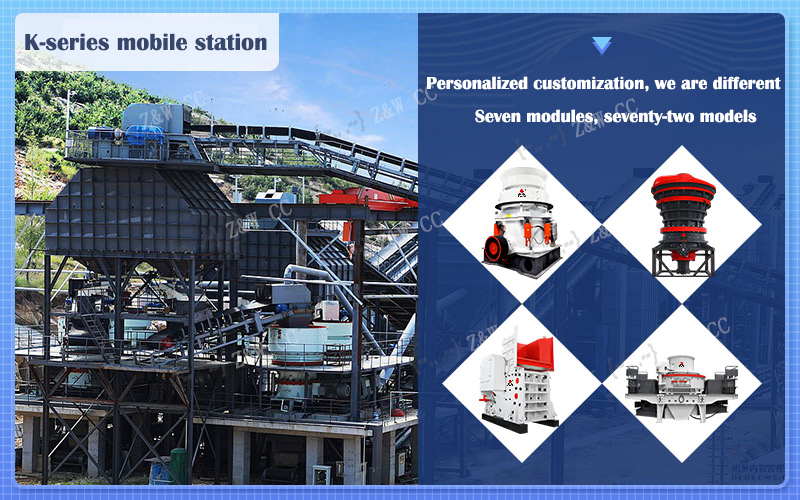

The main equipment of the sand and gravel crushing production line includes vibrating feeder, cone crusher, sand making machine, vibrating screen, conveyor, etc.

Vibrating feeder: The main function is to continuously and evenly feed raw materials into the crusher for crushing.

Cone Crusher: It is used for primary crushing of bulk materials and breaking them into medium-sized pieces.

Sand making machine: further crush medium-sized block materials into sand and gravel materials that meet the specifications.

Vibrating screen: used to classify sand and gravel according to specifications, and transport sand and gravel of different sizes separately.

Conveyor: Transport sand and gravel of different specifications to designated storage locations.

Sand and gravel crushing production line process

Raw material collection: Collect the materials that need to be crushed to the starting position of the production line.

Primary crushing: Send the collected bulk materials into the cone crusher for primary crushing through the vibrating feeder, and crush them into medium-sized blocks.

Secondary crushing: Send the medium block materials after the primary crushing to the sand making machine for secondary crushing, and crush them into sand and gravel materials that meet the specifications.

Screening: The sand and gravel after the secondary crushing are screened by a vibrating screen, and the sand and gravel of different specifications are transported separately.

Quality inspection: Carry out quality inspection on sand and gravel materials of different specifications to ensure that they meet the specified physical and chemical performance requirements.

Storage and transportation: Store the qualified sand and gravel in designated storage locations, and transport them to subsequent production or use links through conveyors.

If you are interested in or have questions about our products, please call us at +86 15538087625 or click “Business Connect” for consultation at any time. Our customer service personnel will provide you with detailed answers and considerate services. Your satisfaction will be our unremitting driving force. You are welcome to click for consultation.