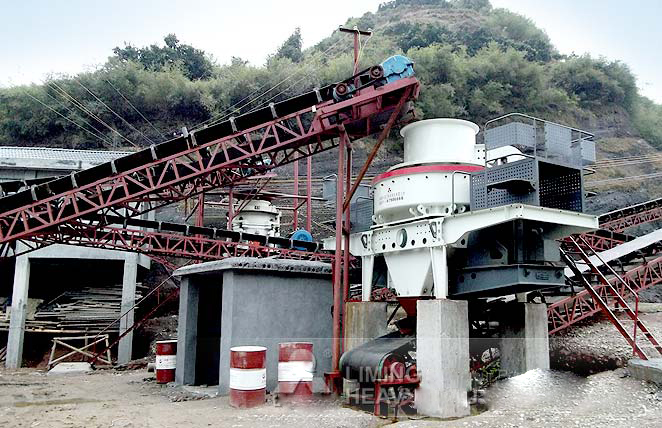

Iron ore beneficiation involves processes to improve the quality of iron ore by removing impurities and increasing its iron content. Crushers play a crucial role in this process by reducing the size of iron ore lumps for further processing.

Iron Ore Beneficiation Process Overview:

1. Crushing: Large iron ore lumps are crushed into smaller particles (typically <10mm) using primary, secondary, and tertiary crushers.

2. Screening: Separates crushed ore into different size fractions.

3. Grinding: Further reduces particle size (to ~100-200 microns) for liberation of iron minerals.

4. Magnetic Separation / Flotation / Gravity Separation: Removes impurities like silica, alumina, and phosphorus.

5. Pelletizing/Sintering: Agglomerates fine particles for blast furnace use.

Crusher Capacity for Iron Ore Processing

The capacity of crushers used in iron ore beneficiation plants varies based on:

- Type of crusher (Jaw Crusher, Gyratory Crusher, Cone Crusher, Impact Crusher)

- Feed size and hardness of iron ore

- Desired product size

- Plant throughput requirements

- Small-scale plant: 100–500 mt/h

- Medium-scale plant: 500–2,000 mt/h

- Large-scale plant: 2,000–10,000+ mt/h

Typical Crusher Capacities (Metric Tons per Hour – mt/h):

| Crusher Type | Capacity Range (mt/h) |

|———————-|———————–|

| Primary Jaw Crusher | 50 – 1,500 |

| Gyratory Crusher | 500 – 5,000 |

| Cone Crusher | 100 – 1,200 |

| Impact Crusher | 50 – 800 |

Example Plant Capacities:

Key Considerations:

1. Ore Characteristics: Hardness (e.g., hematite vs. magnetite), moisture content.

2. Downstream Processes: Higher capacity needed if grinding requires finer feed.

3. Maintenance & Wear: Iron ore is abrasive; crushers must be wear-resistant.

Would you like details on specific crushers or optimization techniques?

Leave a Reply