Certainly! Below is an illustration and explanation of a Single Toggle Jaw Crusher, a common type of primary crusher used in mining and aggregate industries.

—

Single Toggle Jaw Crusher Diagram

Here’s a simplified representation:

`

Fixed Jaw Plate

_________________

/ \

/ \

/ \

/ \

/ \

_______/ \_______

Moving Jaw Plate (attached to Pitman)

| |

|←Crushing Force→| |

| |

Eccentric Shaft → ( ) ← Toggle Plate

|

Motor & V-Belt Drive

`

—

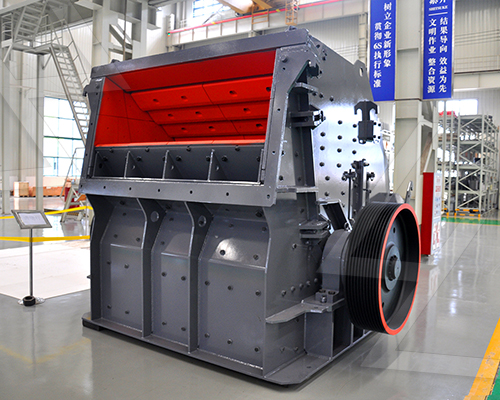

Key Components & Working Principle

1. Fixed Jaw Plate – Stationary crushing surface attached to the crusher frame.

2. Moving Jaw Plate – Swings in an elliptical motion due to the eccentric shaft.

3. Eccentric Shaft – Rotates via motor and belt drive, creating the oscillating motion.

4. Toggle Plate – Acts as a safety mechanism and helps transmit crushing force.

5. Pitman – Connects the moving jaw to the eccentric shaft.

6. Spring Return System – Ensures the jaw returns after crushing..jpg)

—

How It Works

- The motor drives the eccentric shaft via belts/pulleys.

- As the shaft rotates, the pitman moves elliptically, forcing the moving jaw against the fixed jaw.

- Material fed into the crushing chamber is compressed and broken into smaller pieces.

- The crushed material exits through the discharge opening at the bottom.

—

Advantages of Single Toggle Design

✔ Simpler construction than double toggle

✔ Lower maintenance

✔ Higher capacity for given size

✔ Efficient crushing motion

Would you like a more detailed CAD-style diagram or specific dimensions? Let me know how I can refine this illustration!

Leave a Reply