A mill for grinding talc must be carefully selected to ensure efficient particle size reduction while maintaining the mineral’s softness, brightness, and purity. Talc (hydrated magnesium silicate) is a soft mineral (Mohs hardness of 1), making it relatively easy to grind but also prone to contamination if improper equipment is used.

Recommended Mills for Talc Grinding

1. Jet Mill (Fluid Energy Mill)

– Ideal for ultrafine grinding (D97 < 10 µm).

– Uses high-pressure air or steam to achieve particle-on-particle impact grinding.

– Prevents contamination since no grinding media is used.

– Maintains talc’s whiteness and purity.

2. Ball Mill

– Suitable for medium to fine grinding (~45–100 µm).

– Uses ceramic or alumina balls to minimize contamination.

– Requires classification (e.g., air classifier) for finer particle control.

3. Raymond Roller Mill

– Best for coarse to medium-fine grinding (~80–325 mesh).

– Uses rollers and a rotating table for compression grinding.

– Energy-efficient but may not achieve ultrafine sizes.

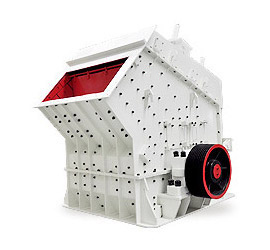

4. Hammer Mill

– Used for coarse grinding (~200–500 µm).

– Impact-based crushing with hammers; risk of iron contamination if metal wear parts are used.

5. Attrition Mill / Stirred Media Mill

– Effective for ultrafine and nano-sized talc particles (<5 µm).

– Uses ceramic or polymer beads in a stirred chamber.

Key Considerations

- Purity: Avoid mills with metal components that could introduce impurities (e.g., iron contamination reduces brightness). Ceramic-lined mills are preferred.

- Particle Size Control: Jet mills or ball mills with classifiers allow precise fineness adjustment.

- Moisture Sensitivity: Talc absorbs moisture; drying may be required before milling.

- Energy Efficiency: Jet mills consume more energy than roller mills but produce finer particles.

Final Recommendation

For ultrafine talc powder (D97 < 10 µm), a jet mill is optimal due to its contamination-free operation and precise particle control. For coarser grades (45–100 µm), a ceramic-lined ball mill or Raymond roller mill works well.

Would you like recommendations on specific manufacturers or additional processing steps like surface modification?

Leave a Reply